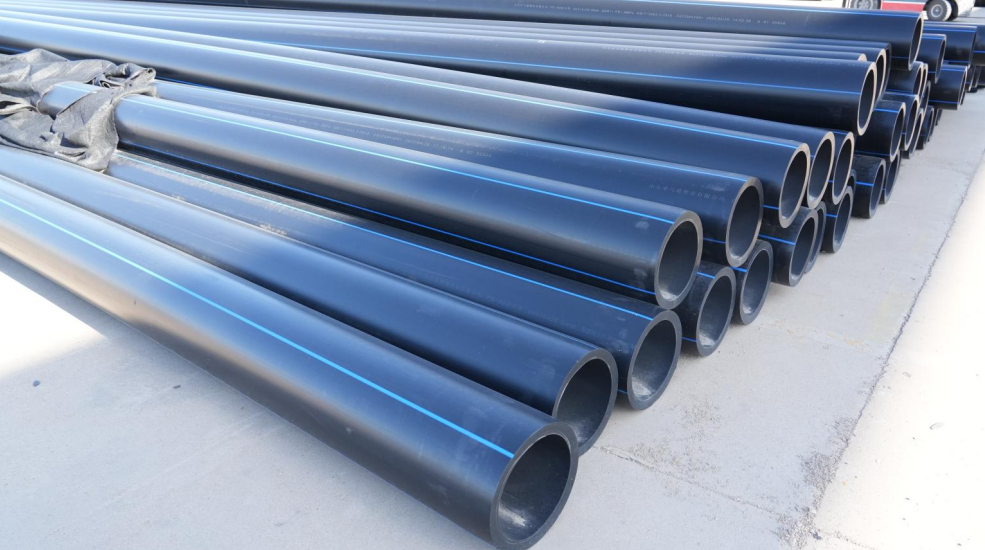

HDPE water pipes have been used for drinking water applications since the 1960s and have been recognized and developed within municipal authorities since then. Some unique advantages of HDPE pipes can bring significant benefits to water applications, as follows:

Corrosion Resistance and Chemical Resistance

- HDPE pipes do not corrode, form tuberculation, or allow microbial growth. They have a smooth inner diameter, maintaining their flow capacity for extended periods. HDPE pipes exhibit excellent chemical resistance, making them the preferred material in harsh chemical environments.

- Compared to traditional metal pipes, many plastic pipes have the advantage of corrosion resistance and chemical resistance, but HDPE pipes uniquely combine these attributes with the advantages of heat-fused joints, flexibility, and fatigue resistance.

Durability

- HDPE pipes can be joined together through heat fusion to form joints that are as strong as or even stronger than the pipe itself, with no leaks.

- This eliminates potential leak points every 10-20 feet present in PVC and ductile iron bell and spigot connections.

- The lifecycle cost of HDPE pipes sets them apart from other pipe materials due to the absence of any "allowable leakage," a contrast to the usual leakage rates of 10% to 20% seen in PVC and ductile iron pipes.

- HDPE pipe fusion joints have self-restraint capabilities, eliminating the need for expensive thrust restraint devices or thrust blocks.

- Heat-fused joints of HDPE pipes do not leak at all, thus eliminating the penetration and leakage issues encountered by other pipe joints.

Flexibility and Fatigue Resistance

- The bending radius of HDPE pipes can reach up to 25 times the nominal pipe diameter (e.g., a 12-inch HDPE pipe can be cold-formed in the field to a 25-foot radius), reducing the need for many fittings required for directional changes in the pipeline system.

- The flexibility of HDPE pressure pipes makes them ideal for dynamic soils, including earthquake-prone areas.

- HDPE pressure pipes can withstand repeated pressure fluctuations significantly exceeding the pipe's static pressure rating.

Handling — Benefits

- Structurally, HDPE pipes are easier to handle and install compared to heavier, more rigid metal or concrete pipe sections, providing significant cost advantages during the construction process.

- In terms of structure, HDPE pipes are more impact-resistant than PVC pipes, especially during installation in cold weather, where other pipes are more prone to cracking and fracturing.

Cost-Effectiveness and Long-Term Benefits

HDPE pipe installation costs are low and offer long-term cost advantages due to its physical properties, leak-free joints, and reduced maintenance costs.

The HDPE pipe industry estimates a conservative service life of 50-100 years, leading to cost savings in pipe replacement for future generations.

You are welcome to : phone call, Message, Wechat, Email& Seaching us, etc.