About HDPE

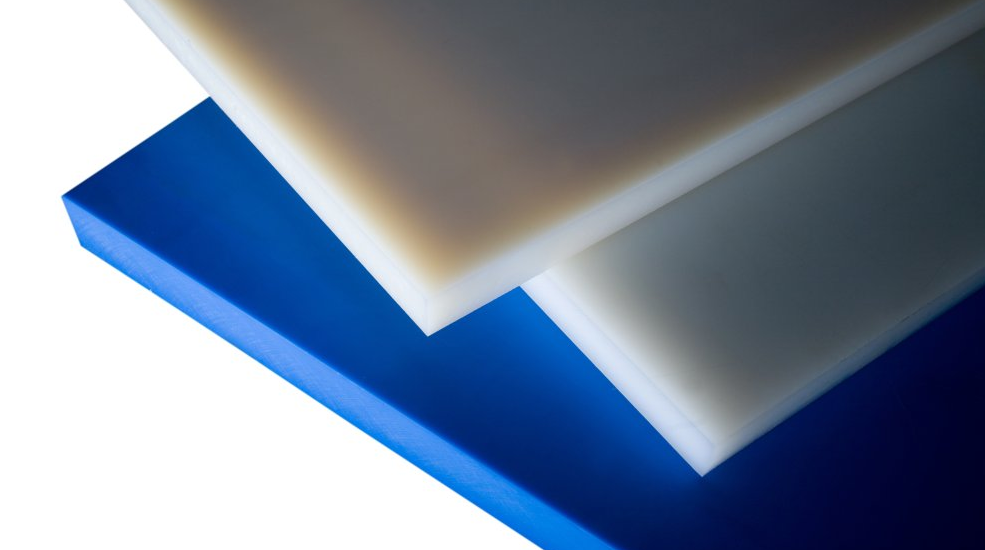

HDPE, or High-Density Polyethylene, is a thermoplastic polymer produced through the polymerization of ethylene monomers.Known for its high strength and density, usually ranging from 0.93 to 0.97 g/cm³, HDPE is a durable and versatile material.It is widely used in the production of plastic bottles, corrosion-resistant pipes, geomembranes, and plastic lumber.HDPE is impact-resistant, weather-resistant, and chemically resistant, making it suitable for various industrial and consumer applications.Additionally, HDPE is recyclable and is often used in environmentally friendly projects.

Typical Properties of HDPE

- High Strength-to-Density Ratio

HDPE has high tensile strength, making it strong and durable while remaining lightweight. - Chemical Resistance

HDPE is highly resistant to a variety of chemicals, including acids, alkalis, and solvents, making it ideal for containers and pipes. - Low Moisture Absorption

It absorbs very little moisture, which helps maintain stability and performance in humid environments. - Weather Resistance

HDPE can withstand UV radiation and extreme temperatures, making it durable outdoors without degrading. - Impact Resistance

HDPE is tough and flexible, with excellent impact resistance even at low temperatures. - Flexibility

While strong, HDPE retains some flexibility, making it useful in applications where movement or pressure changes are expected. - Non-Toxic

HDPE is free from toxins and is safe for use in containers that hold food and beverages. - Recyclability

HDPE is 100% recyclable, making it an environmentally friendly choice.

These characteristics make HDPE a popular choice in applications ranging from pipes and containers to automotive parts and playground equipment.

Does HDPE Comply with FDA Requirements?

HDPE complies with the U.S.Food and Drug Administration (FDA) requirements for food contact materials.Specifically, HDPE is used in materials that come into direct contact with food and beverages for the following reasons:

- Material Purity

HDPE has a high purity level and does not contain harmful substances, meeting the FDA's stringent requirements for food contact materials.The FDA mandates that HDPE must avoid contact with certain harmful substances (such as heavy metals and plasticizers) during manufacturing and use, which is strictly adhered to. - Non-Toxicity

The chemical structure of HDPE is very stable and does not react with food or beverages, preventing the migration of any harmful chemicals.This makes HDPE safe for use in food packaging, in accordance with FDA regulations. - Low Migration Rate

HDPE does not release harmful chemicals under temperature changes (such as freezing or heating), and its migration rate (the amount of chemical substances migrating from packaging material into food) is very low, meeting the FDA's food safety standards. - Suitable for Various Food Packaging

The FDA allows HDPE to be used in the manufacture of various food packaging materials, such as milk bottles, juice containers, frozen food packaging, and bags for fresh produce.These products have been rigorously tested and certified for safety and effectiveness.

Does HDPE have Antibacterial Properties?

HDPE itself does not have natural antibacterial properties.As a polymer material, HDPE's main characteristics include high strength, chemical resistance, low water absorption, and weather resistance, but it does not inherently inhibit or kill microorganisms such as bacteria, fungi, or viruses.

However, antibacterial properties can be imparted to HDPE by adding antimicrobial agents during the manufacturing process or through special surface treatments.These agents or treatments can help inhibit microbial growth on the material's surface, enhancing its functionality in certain applications.

It is important to note that even with the addition of antimicrobial agents, the antibacterial effect of HDPE is usually limited to the material's surface and may diminish over time and with increased use.Therefore, regular cleaning and maintenance are still necessary in applications where hygiene and safety are critical.

How Does HDPE Perform Outdoors?

HDPE typically performs exceptionally well in outdoor environments, as evidenced by the following:

- Weather Resistance

HDPE can maintain stable performance in extreme temperatures, withstanding both high temperatures (up to 120°C) and retaining toughness and impact resistance at low temperatures (down to40°C).This allows HDPE to maintain its physical properties in various climate conditions.Additionally, it has strong resistance to ultraviolet (UV) radiation and will not degrade quickly when exposed to sunlight for extended periods. - Water Resistance

HDPE is virtually waterproof, with excellent water and moisture resistance, making it especially suitable for outdoor applications that require waterproofing, such as pipes, geomembranes, and tarpaulins. - Chemical Resistance

HDPE is highly resistant to many chemicals, including acids, alkalis, and salts, enabling it to remain stable in corrosive environments.This characteristic makes HDPE highly effective in outdoor applications such as agricultural irrigation systems and chemical pipelines. - Impact Resistance

HDPE materials have good impact resistance, retaining sufficient toughness even at low temperatures.This means they can withstand mechanical damage in outdoor environments, such as impacts or crushing.

What is the Difference Between HDPE and LDPE?

HDPE and LDPE differ significantly in structure, physical properties, and application scenarios.

HDPE and LDPE are both versatile plastic materials widely used in different applications due to their unique physical and chemical properties.HDPE is known for its high strength, rigidity, and chemical resistance, making it suitable for manufacturing durable products; LDPE, on the other hand, is valued for its flexibility and transparency, primarily used in soft packaging and flexible products.The choice between HDPE and LDPE depends on specific application needs, such as the requirement for higher strength or greater flexibility.

What are Common Applications of HDPE?

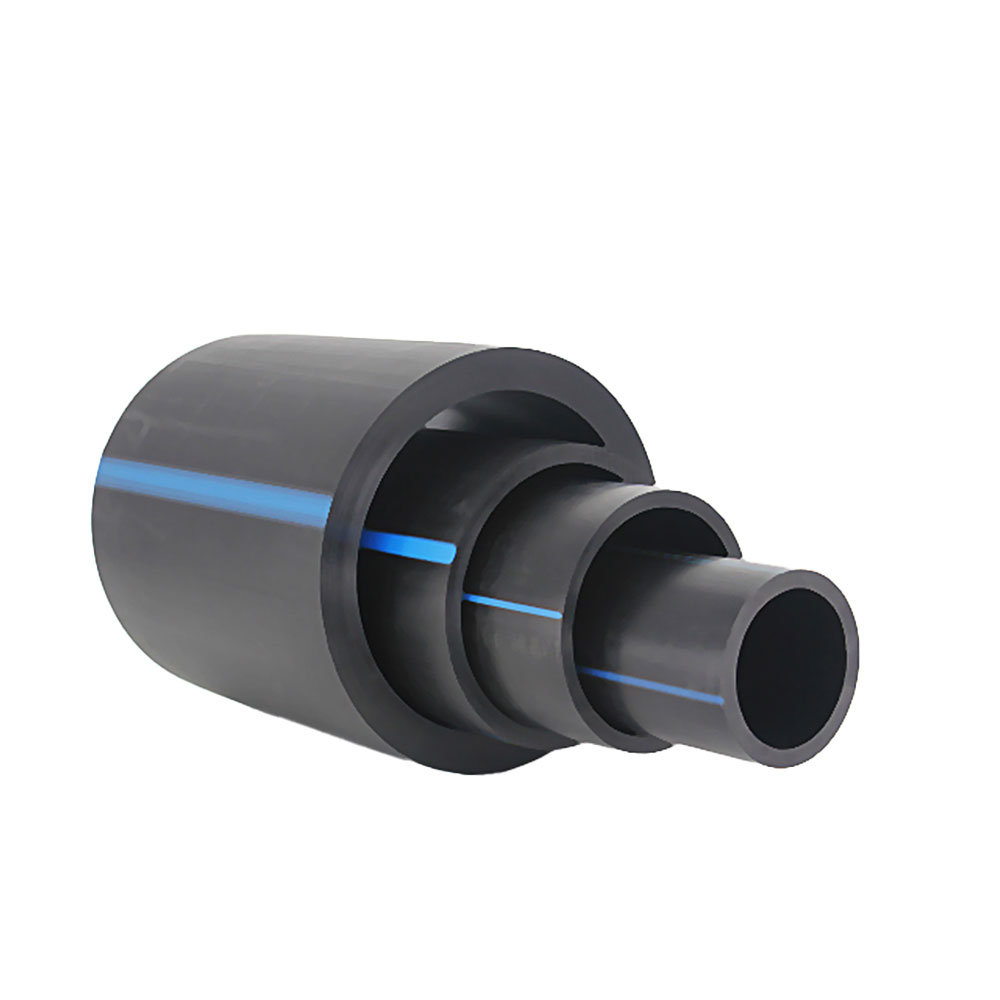

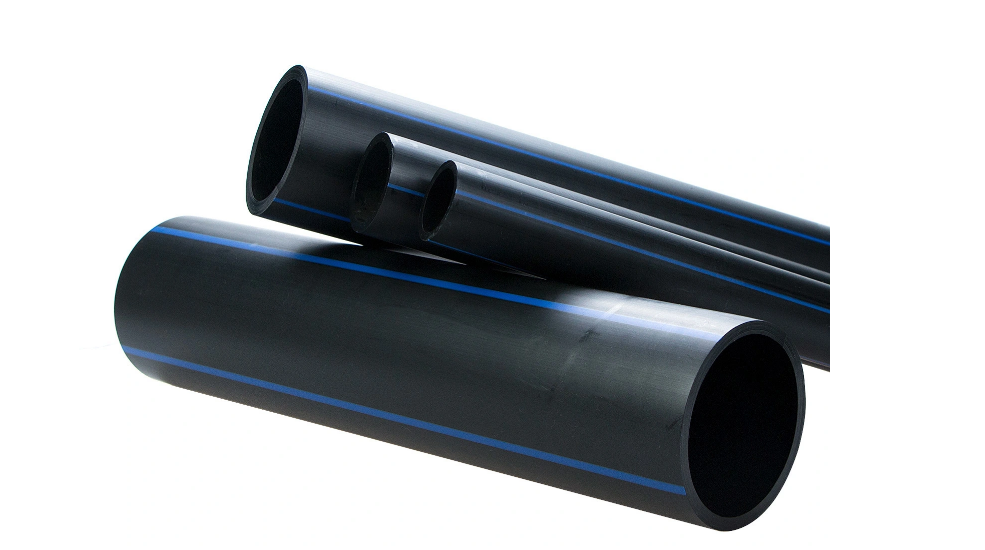

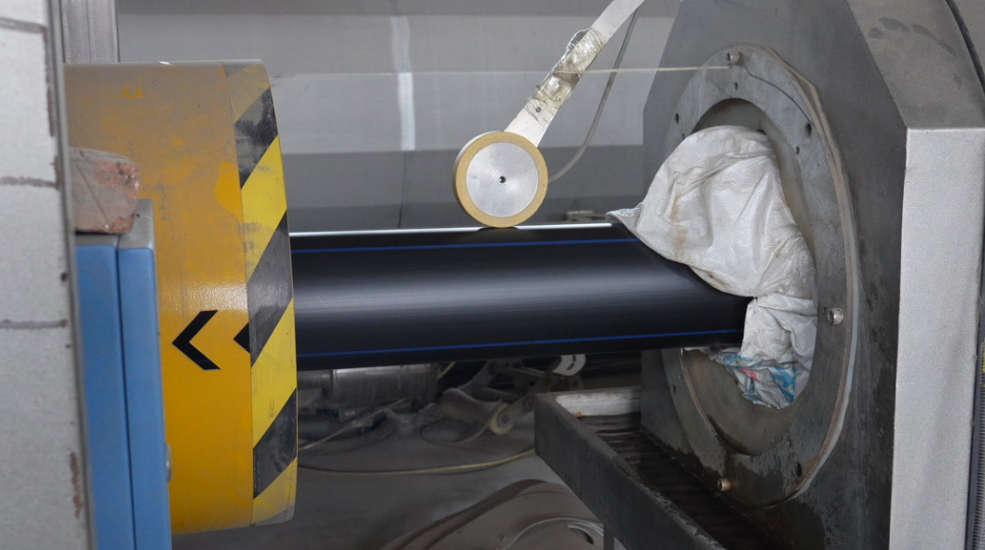

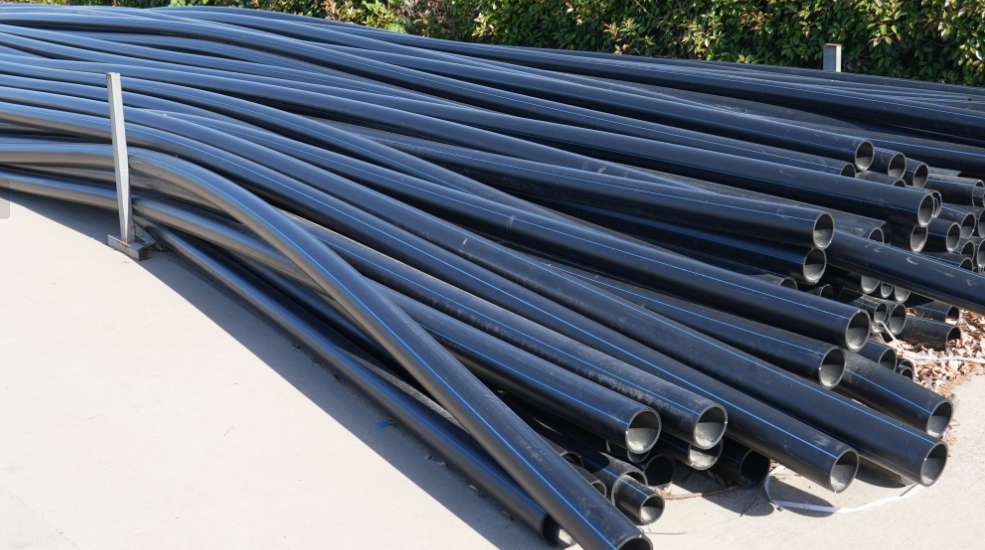

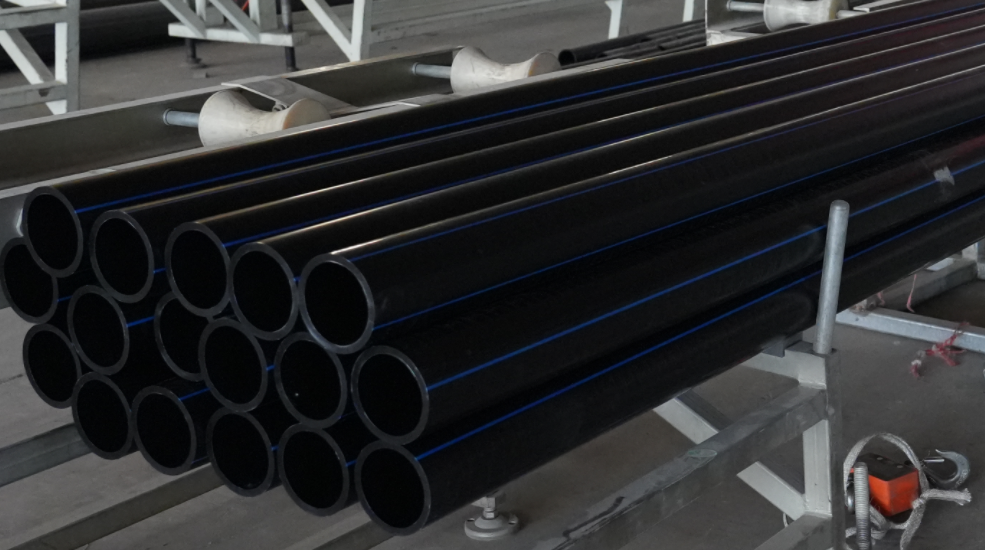

- Pipes and Tubes

Water Supply Pipes:HDPE's corrosion resistance and pressure-bearing capabilities make it an ideal choice for water supply pipes, especially in potable water distribution systems.

Gas Pipes:HDPE pipes are widely used for the transport of natural gas and liquefied petroleum gas (LPG) due to their chemical corrosion resistance, impact resistance, and good flexibility.

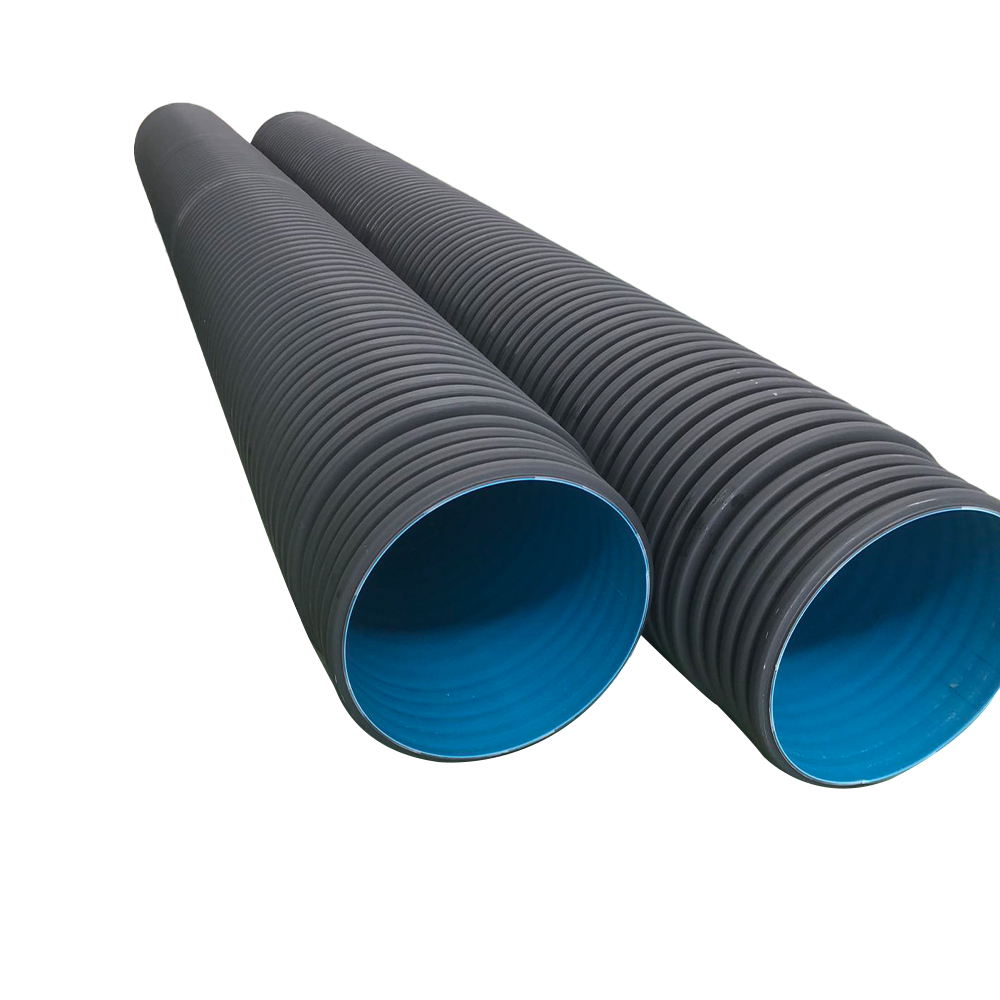

Sewage Treatment Pipes:HDPE's chemical resistance makes it suitable for sewage and wastewater treatment system pipes.

- Building

Waterproof Membranes:HDPE is used as a waterproof layer in buildings, commonly applied in basement, roof, and tunnel waterproofing projects.

Geomembranes:HDPE geomembranes are used in landfill, tailings treatment, pond liners, and other projects requiring impermeable barriers.

Construction Fencing:HDPE's weather resistance and impact resistance make it suitable for outdoor construction fencing and fencing materials. - Agricultural Applications

Irrigation Systems:HDPE pipes and fittings are widely used in agricultural irrigation systems due to their chemical resistance, wear resistance, and flexibility.

Greenhouse Films:HDPE is used to manufacture covering films for agricultural greenhouses due to its UV resistance and weatherability, allowing it to be exposed to outdoor environments for long periods. - Industrial Products

Chemical Containers:HDPE is used to make chemical containers, such as barrels and tanks, which have good chemical corrosion resistance, making them suitable for storing and transporting various chemicals.

Cable Protection Tubes:HDPE is used to manufacture protective tubes for power and communication cables due to its weather resistance and high mechanical strength.

You are welcome to : phone call, Message, Wechat, Email& Seaching us, etc.