Introduction

In the fast-evolving world of water management, High-Density Polyethylene, or HDPE, has gained momentum as a top-choice material for sustainable water systems. Known for its durability, flexibility, and resistance to corrosion, HDPE offers unparalleled benefits in various water transportation applications. From HDPE water pipes and HDPE water mains to HDPE water bottles, this material's applications continue to grow, providing efficient, reliable, and eco-friendly solutions across multiple industries.

Advantages of HDPE Material

- Corrosion Resistance

Unlike traditional metal pipes, HDPE is highly resistant to corrosion, making it ideal for long-term water transportation. This anti-corrosive property also prevents contamination, ensuring clean water flows through the pipes. - Flexibility and Strength

HDPE pipes offer a unique balance of flexibility and durability, capable of bending without breaking under pressure. This adaptability allows HDPE piping to endure different terrains and soil movements, which is essential for regions prone to shifting ground or seismic activity. - Environmentally Friendly

HDPE is a sustainable choice, as it can be recycled and reused without leaching harmful chemicals. This quality makes HDPE suitable for potable water applications and is a significant advantage over other plastic or metal materials. - High Impact Resistance

The high-impact resistance of HDPE prevents the pipes from cracking, even under heavy loads or impacts. This feature makes it suitable for installations where pipes might experience pressure changes or impacts from external forces.

Applications of HDPE in Water Transportation

- HDPE Water Mains

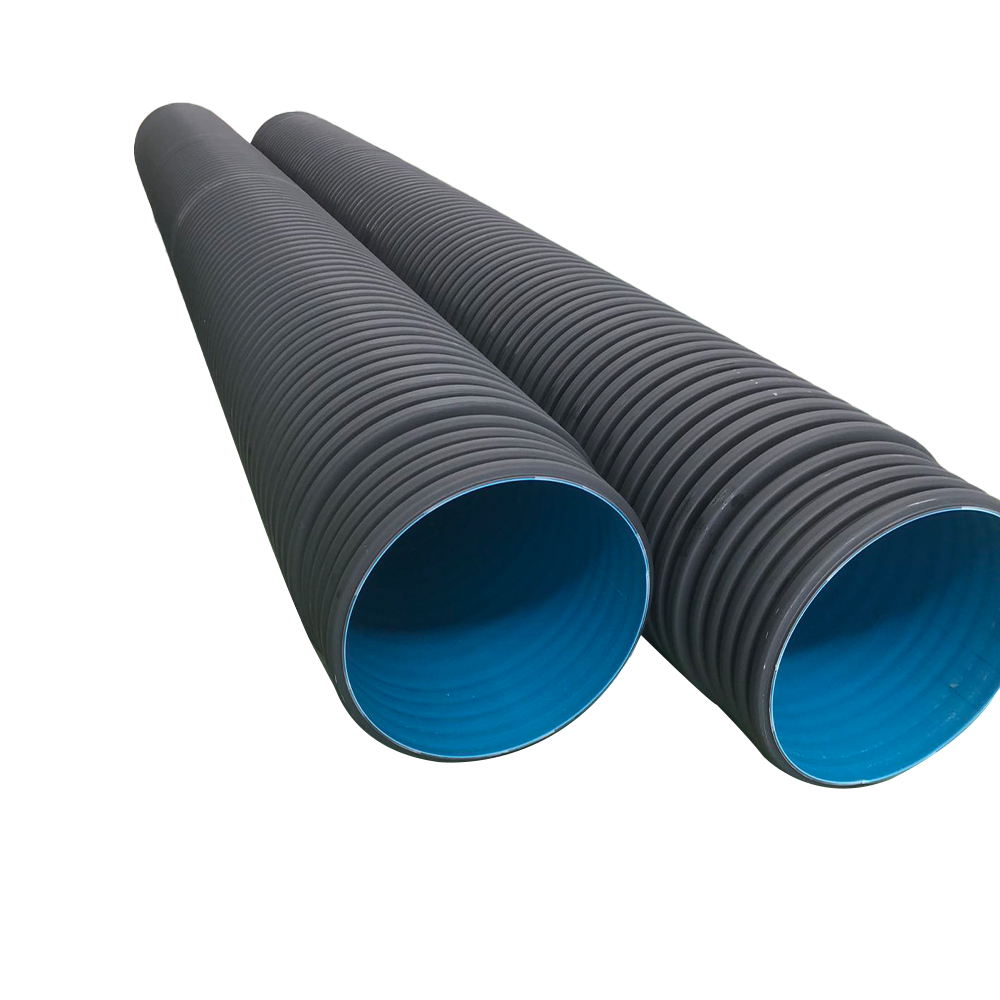

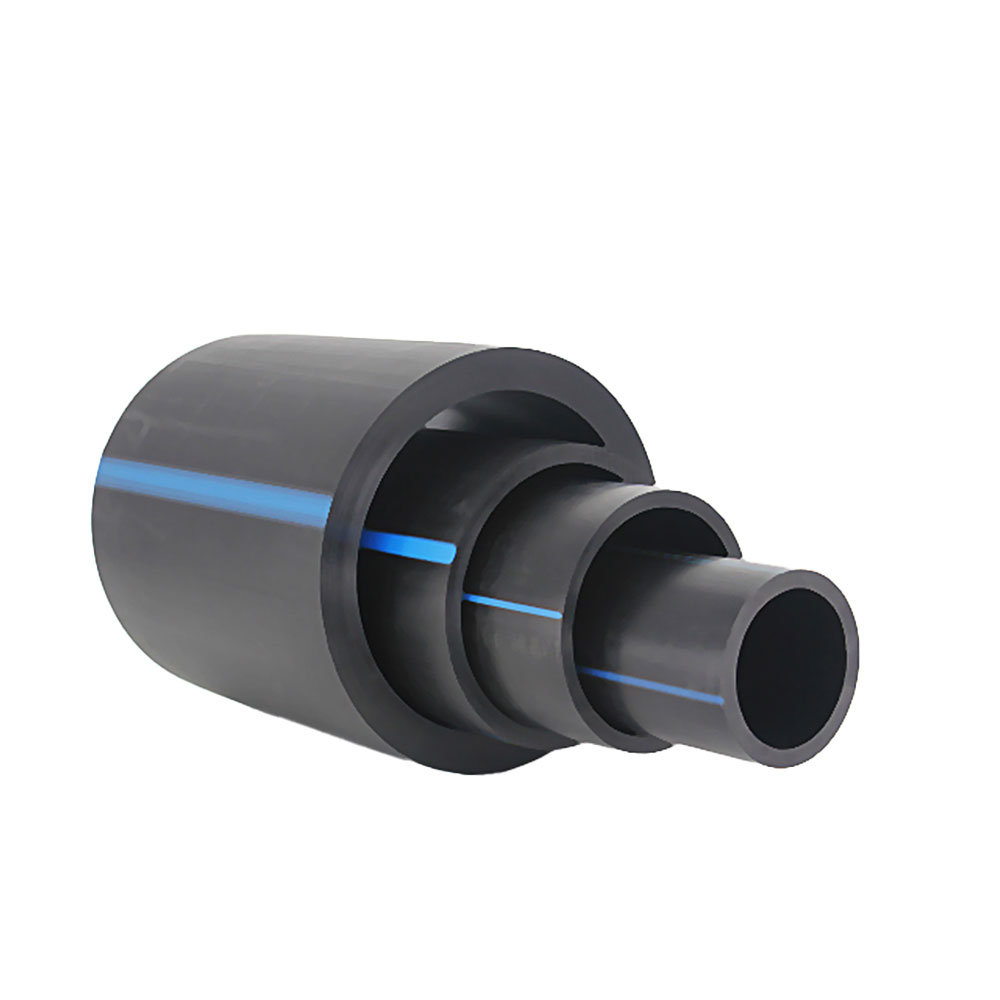

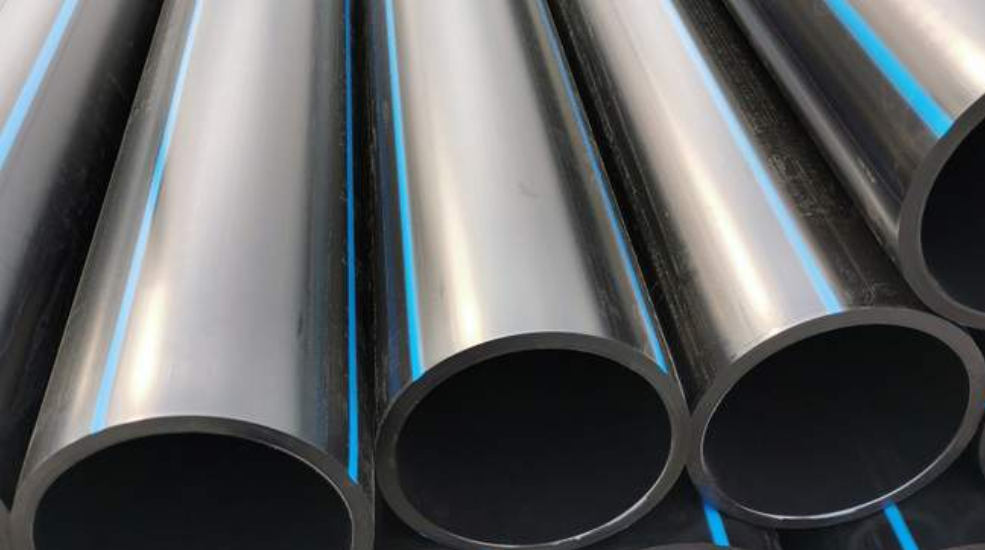

In municipal water systems, HDPE is commonly used for main pipelines due to its ability to maintain consistent water pressure and volume over long distances. These HDPE water mains are highly resistant to environmental stressors, providing dependable service in urban and rural areas alike. Municipalities increasingly favor HDPE for water main infrastructure upgrades as it outlasts many other piping materials, reducing the need for frequent replacements and repairs. - HDPE Pipe for Water Supply

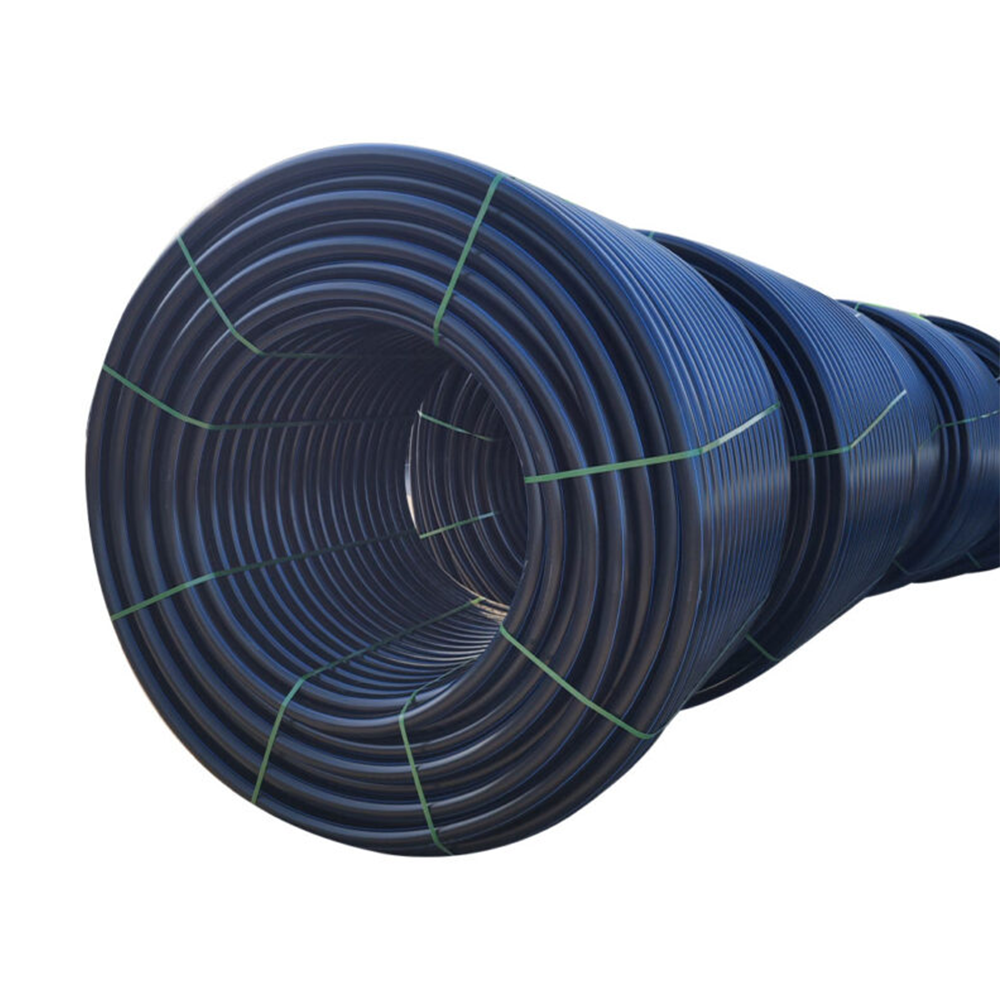

HDPE water supply pipes are specially manufactured for drinking water supply and are designed to meet high health and safety standards. These pipes are preferred in residential, industrial, and commercial water systems due to HDPE's non-leaching characteristics and durability. HDPE's flexibility makes it ideal for installation in areas with difficult terrains, providing clean, drinkable water with minimal risk of contamination. - Polyethylene Pipes (Poly Pipes)

Commonly referred to as poly pipes, HDPE’s polyethylene-based pipe systems are broadly used in agricultural settings, irrigation systems, and landscaping. These pipes are favored in agriculture due to their ability to handle water and nutrient solutions without contamination. HDPE’s high-density structure makes it resistant to chemicals and fertilizers, making it an ideal choice for irrigation lines and drip systems in farming.

HDPE Pipe System Installation and Maintenance

- Electrofusion

This method involves using a specialized fitting that contains an integrated electrical coil. When an electric current is passed through the coil, it heats up, melting the HDPE pipe and fitting together to create a seamless joint. Electrofusion is a preferred method in tight spaces where conventional joining methods might be difficult. - Butt Fusion Welding

Butt fusion involves heating the ends of two HDPE pipes and pressing them together under controlled conditions. This process creates a uniform, continuous connection without the need for additional jointing materials. Butt fusion welding is highly effective for creating long, straight runs of HDPE piping, providing strong and durable bonds that withstand high-pressure applications.

HDPE pipes are known for requiring minimal maintenance due to their inherent durability and resistance to environmental factors. The pipes are resistant to most chemicals, sediments, and biological growth, all of which can typically degrade other materials. This reduced maintenance need makes HDPE an attractive option for projects aiming to minimize operational costs over time.

Eco-Friendly Benefits of HDPE

- Low Energy Production

Producing HDPE requires less energy compared to other plastics, resulting in a reduced carbon footprint. Additionally, HDPE is lightweight, which reduces transportation emissions. - Recyclability

HDPE can be recycled and reused for various applications, reducing landfill waste and conserving resources. HDPE pipes, once they reach the end of their life, can be repurposed into new HDPE products, supporting a circular economy. - Safe for Potable Water

HDPE's non-leaching properties make it a safe option for drinking water transportation and storage. This is particularly beneficial for HDPE water bottles and piping systems designed for potable water supply, as HDPE does not release harmful substances that could contaminate the water.

You are welcome to : phone call, Message, Wechat, Email& Seaching us, etc.