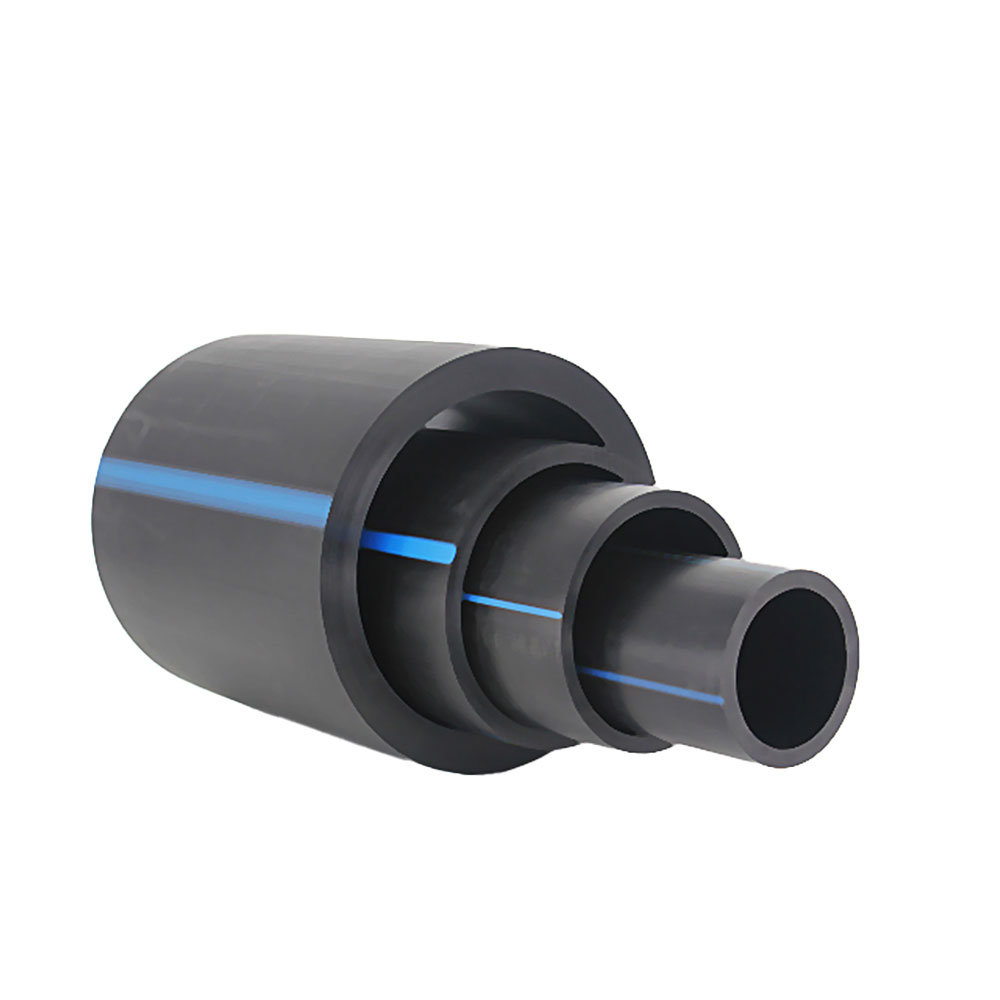

High-Density Polyethylene (HDPE) pipe is primarily joined using various methods, each tailored for specific applications and installation conditions. The main techniques for connecting HDPE pipes include:

Butt Fusion

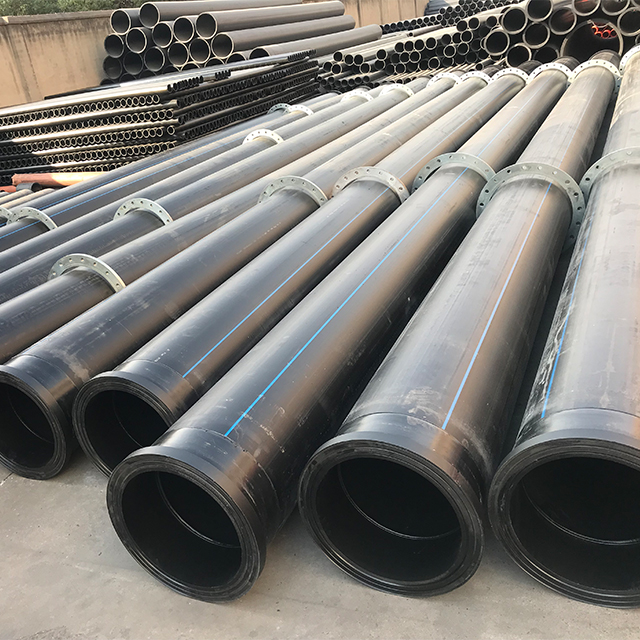

- Most Common Method: Butt fusion is the predominant technique for joining HDPE pipes, particularly in larger diameter applications.

- Process: The ends of two pipes are heated until they become molten and then pressed together to create a joint. The pipe ends are secured in a fusion machine, where heat and pressure meld them into a unified joint.

- Advantages: This method produces a robust, seamless joint without the need for fittings, and the connection is as strong as the pipe itself.

Electrofusion

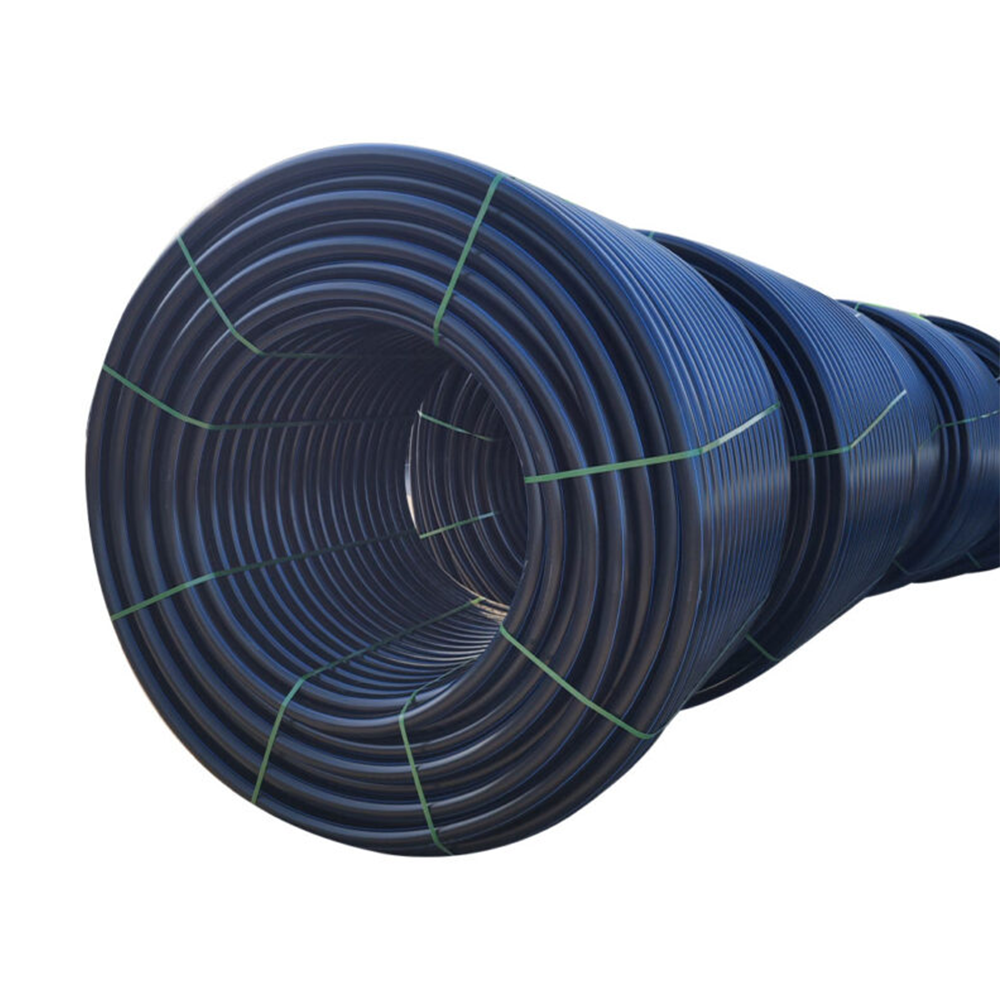

- Used for Smaller Diameter Pipes or Confined Spaces: This technique utilizes electrofusion fittings that have built-in electric heating elements.

- Process: The fitting is placed over the pipe ends, and an electric current is applied, melting both the pipe and fitting, which then fuse together once the current is turned off.

- Advantages: Electrofusion is adaptable, quick, and suitable for smaller pipes or challenging locations. It is also effective for repairs or connections to existing HDPE pipes.

Socket Fusion

- Used for Smaller Pipes: Socket fusion employs a heated tool to melt the ends of the pipe and fitting, which are then joined.

- Process: One end of the HDPE pipe is inserted into a heated socket fitting, softening both components. They are then connected and allowed to cool and solidify.

- Advantages: This method is straightforward and effective for small to medium-sized pipes and fittings.

Mechanical Fittings

- Alternative for Quick or Temporary Connections: Mechanical fittings, such as compression or flange fittings, can connect HDPE pipes without requiring heat or specialized tools.

- Process: These fittings typically use bolts, nuts, or clamps to secure the pipe ends, often incorporating gaskets for a tight seal.

- Advantages: There is no need for fusion equipment, and these joints can be disassembled if necessary. However, they are generally less durable and more susceptible to leaks compared to fusion methods.

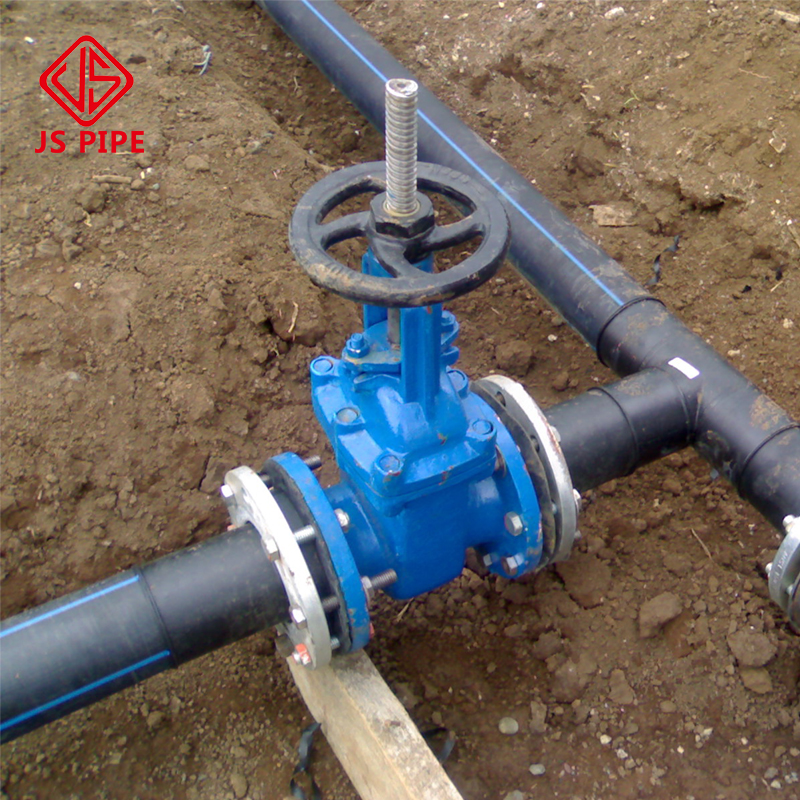

Flanged Connections

- Used for Larger Diameter Pipes or When Disconnection is Necessary**: Flanged connections are utilized in HDPE systems that require frequent disassembly or for very large pipes.

- Process: The ends of the pipes are fitted with flanges and bolted together, often with gaskets to ensure a leak-proof seal.

- Advantages: Flanged connections are highly reliable and facilitate easier disassembly for maintenance or repairs.

Each of these methods has distinct advantages based on the application, pipe size, and installation environment. Butt fusion and electrofusion are the most prevalent techniques for creating permanent, durable joints in HDPE piping systems.

You are welcome to : phone call, Message, Wechat, Email& Seaching us, etc.