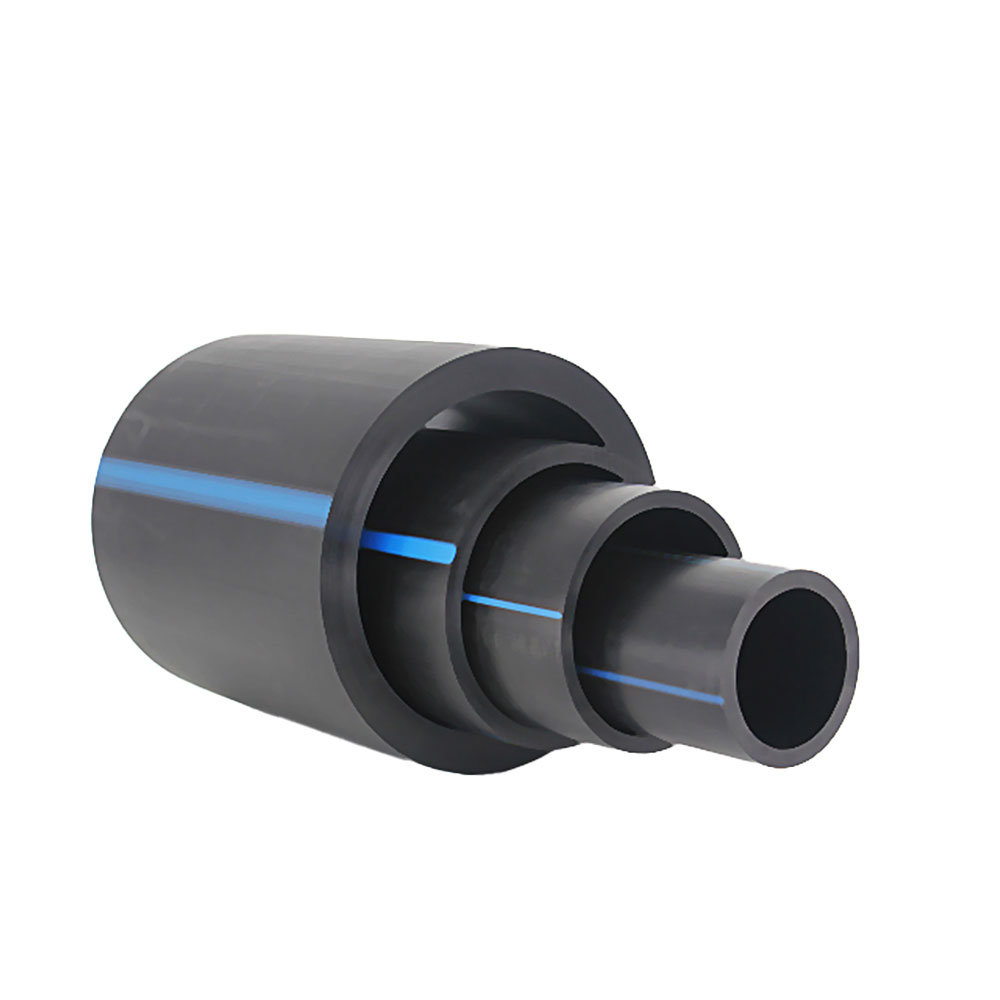

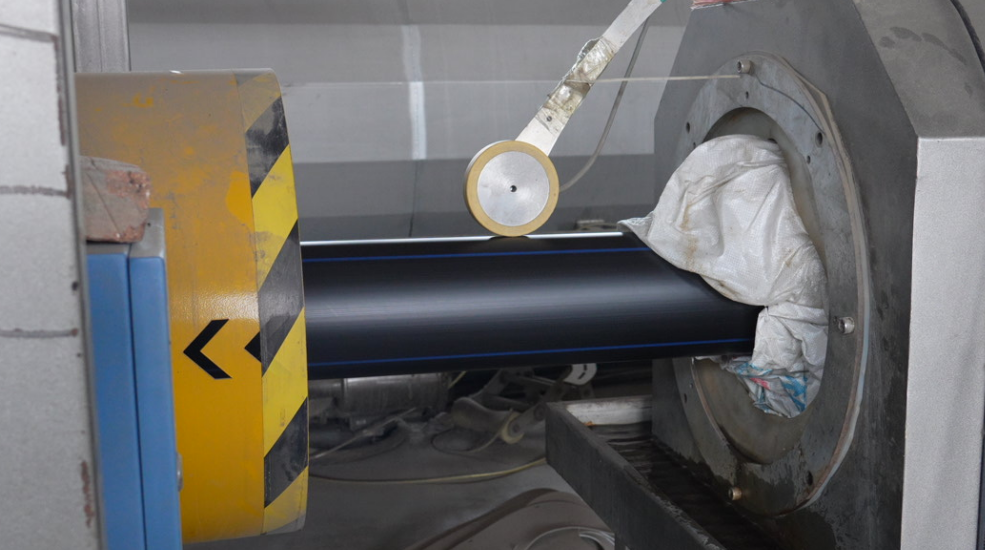

What is an HDPE Pipe?

HDPE pipe, or high-density polyethylene pipe, is a type of high-performance plastic pipe. It is resistant to corrosion, has high strength, good wear resistance, flexibility, and reliable joints. Connections are made through heat fusion or electrofusion, providing excellent sealing and reducing leakage. It is widely used in urban water supply and drainage, gas transportation, agricultural irrigation, and industrial fluid transportation.

Applications of HDPE Pipes

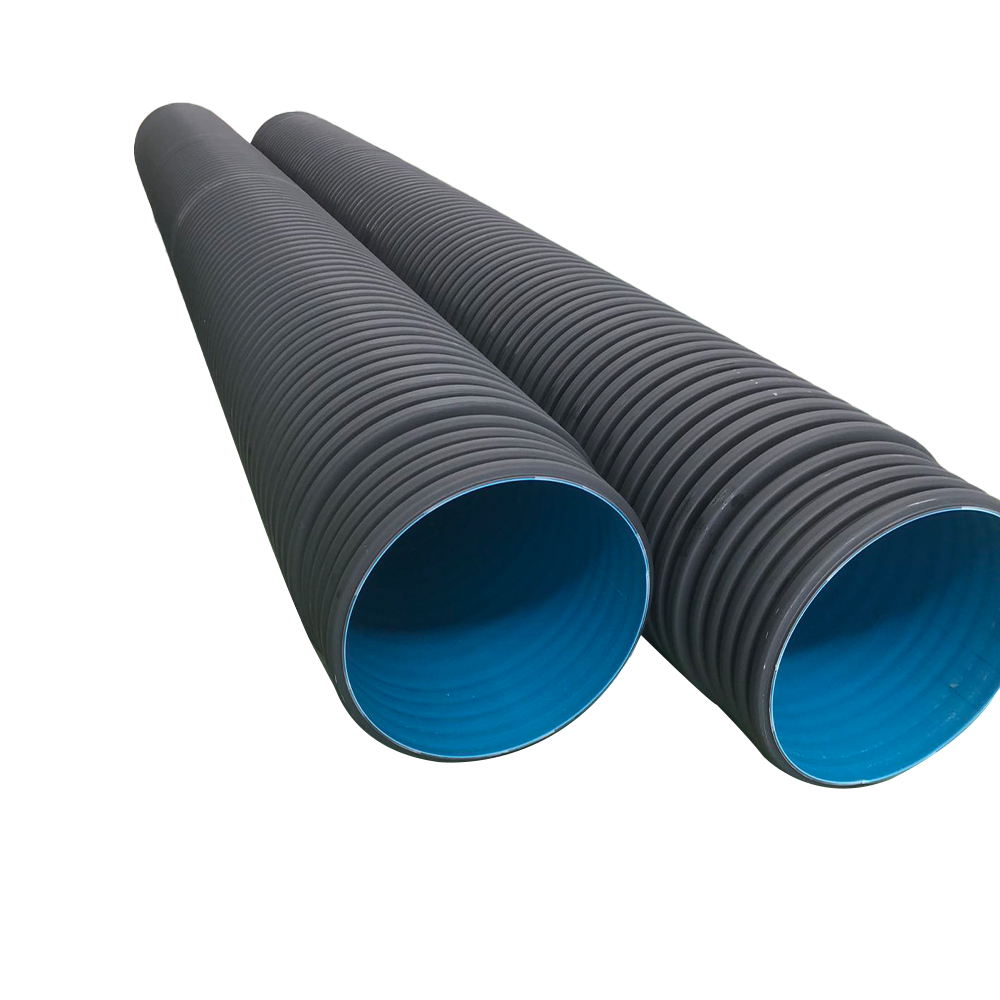

- Municipal Engineering

HDPE pipes are extensively used in urban water supply and drainage systems, safely and effectively transporting drinking water. Their excellent corrosion resistance ensures water quality remains uncontaminated. They can also be used for rainwater and sewage discharge, withstanding underground pressure and corrosion. - Gas Transportation

They can safely and reliably transport natural gas and liquefied gas, with good airtightness, reducing the risk of gas leaks. - Agricultural Irrigation

HDPE is used in agriculture to build efficient irrigation networks, adaptable to various terrains, wear-resistant, and corrosion-resistant, ensuring long-term stable operation. - Industrial Field

They are used in the chemical industry to transport various chemical liquids and raw materials, resisting erosion by many chemicals. In the petroleum industry, they transport crude oil, refined oil, etc. - Communication Cable Protection

As protective casings for communication cables, HDPE material prevents cables from environmental damage.

Advantages of HDPE Pipes

- Strong Chemical Stability

They resist most chemical substances, including acids, bases, and salt solutions, maintaining good performance in harsh chemical environments without easy corrosion and degradation. - Excellent Wear Resistance

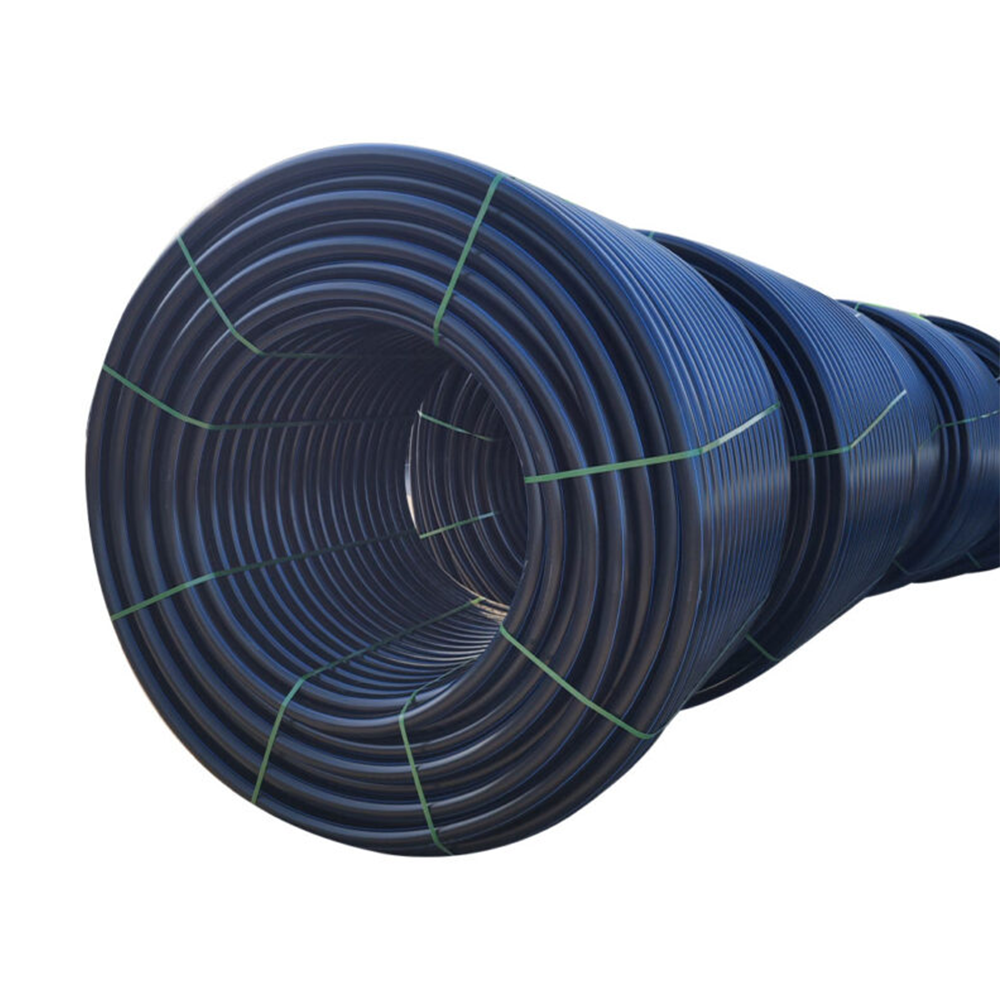

With a smooth inner wall, they have low fluid resistance, reducing friction and wear, extending the pipeline's service life, especially suitable for transporting media containing solid particles. - Good Flexibility

They can be bent and coiled, making them easy to transport and install, especially in complex terrains or confined spaces, flexibly adapting to various routing and layout requirements. - Good Impact Resistance

They can withstand large external impacts and pressure changes, not easily breaking under external forces, providing strong earthquake and subsidence resistance. - Hygienic and Non-toxic

They meet food hygiene standards and will not contaminate the transported media, suitable for drinking water and food industries with high hygiene requirements. - Reliable Connection

Typically using heat fusion or electrofusion connections, forming an integrated structure at the joints with excellent sealing performance, effectively reducing the risk of leakage. - Lightweight

Compared to metal pipes, HDPE pipes are lighter, making them easier to transport and install, reducing construction difficulty and cost. - Economical and Practical

They are relatively affordable, with low maintenance costs and a high cost-performance ratio. - Long Service Life

Under normal conditions, they can last for decades or longer, reducing the frequency of pipeline replacement and maintenance. - Environmentally Friendly and Recyclable

The material itself is environmentally friendly, and after reaching its service life, it can be recycled, meeting sustainable development requirements.

HDPE Pipe Size Selection

- Water Supply

For water supply, consider the population size, peak water consumption, and pressure requirements. Smaller communities may use pipes with an outer diameter of 20-63 mm, while large urban networks may require pipes with diameters of 110-630 mm or larger to meet high water demand and maintain stable pressure. - Drainage Systems

For drainage systems, choose based on the expected drainage volume and speed. Residential areas might use rainwater pipes with diameters of 160-315 mm, while main urban roads or large commercial areas might need pipes over 315 mm. - Gas Transportation

Size selection mainly depends on the gas supply volume and transport distance. Small residential areas might use pipes with diameters of 63-160 mm, while large industrial or city-level gas networks may need pipes over 200 mm to ensure sufficient gas flow and pressure. - Agricultural Irrigation

This depends on the size of the irrigation area, crop type, and irrigation method. Small-scale farms might use pipes with diameters of 50-90 mm, while large farms or efficient systems like sprinklers or drip irrigation may require pipes over 110 mm for sufficient water flow and uniform irrigation. - Industrial Field

The transport of chemical liquids and raw materials depends on the medium's properties, flow rate, and pressure requirements. High flow, high-pressure conditions may need pipes over 200 mm, while smaller flow, low-pressure applications may only require pipes of 50-110 mm.

In summary, when selecting HDPE pipe sizes, consider the specific needs of the application field, including flow, pressure, environment, and installation conditions. Follow relevant industry standards and regulations to ensure the pipeline system operates safely and efficiently.

You are welcome to : phone call, Message, Wechat, Email& Seaching us, etc.