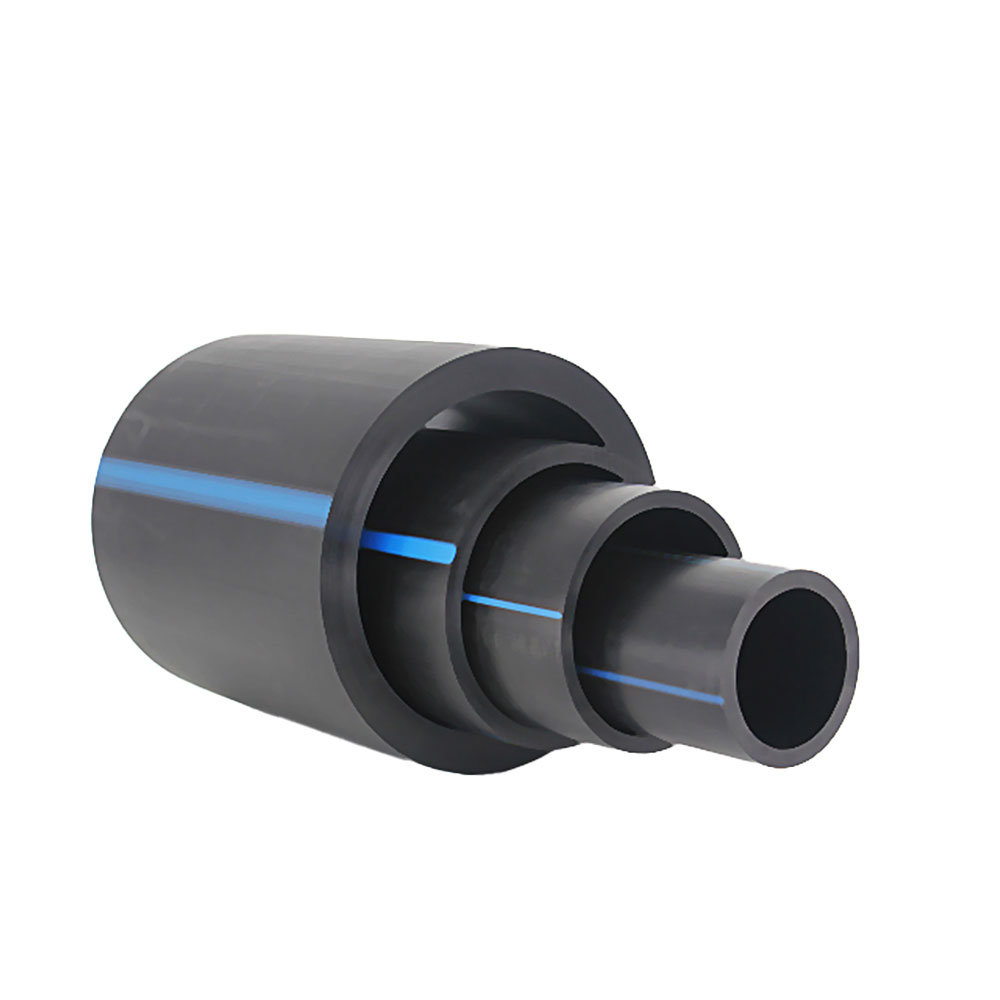

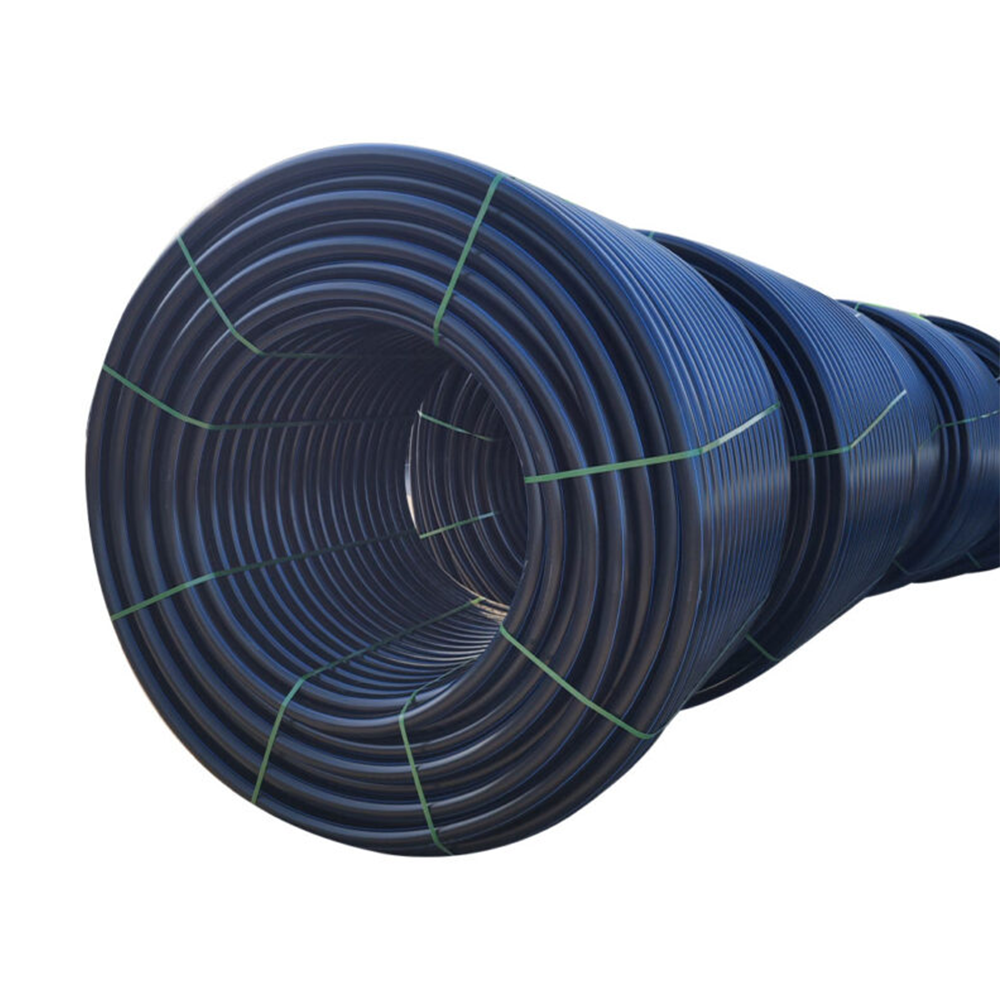

Connecting HDPE (High-Density Polyethylene) pipes is essential for establishing a dependable and long-lasting piping system for water, gas, or industrial uses. There are various methods to connect HDPE pipes, depending on the specific needs of your system and the tools at your disposal. Here are the most common techniques for joining HDPE pipes:

1. Butt Fusion Welding

- Overview: This is the most widely used technique for connecting HDPE pipes. It involves heating the ends of two pipes and pressing them together under pressure to form a strong bond.

- Procedure:

- Cut the pipes: Use a pipe cutter or saw to ensure the ends of the HDPE pipes are square and smooth.

- Clean the ends: Make sure the pipe ends are free from dirt, debris, and moisture.

- Heat the fusion machine: Set up a butt fusion machine with a heating plate to warm the pipe ends.

- Heat the pipe ends: Place the pipes in the machine, where the heating plate will melt the ends.

- Press the pipes together: After the appropriate melt time, remove the heating plate and press the two ends together under controlled pressure.

- Cool and inspect: Allow the welded joint to cool before checking for leaks.

- Required Tools: Butt fusion machine, pipe cutter, and cleaning tools.

2. Electrofusion Welding

- Overview: This method utilizes an electrofusion coupling (a specialized fitting with embedded heating coils) to fuse the pipe ends.

- Procedure:

- Prepare the pipe ends: Clean and trim the ends of the HDPE pipes for a smooth, even surface.

- Install the electrofusion coupler: Position the electrofusion fitting over the ends of the pipes to be connected.

- Secure the fitting: Connect the built-in electrical contacts of the electrofusion fitting to an electrofusion welding machine.

- Weld the joint: Activate the welding machine, which sends an electrical current through the coils, generating heat to melt and fuse the pipes.

- Allow cooling: Wait for the joint to cool before applying any pressure or stress.

- Required Tools: Electrofusion welding machine, electrofusion couplers, pipe cutter.

3. Mechanical Compression Fittings

- Overview: This method uses mechanical fittings, such as compression couplings or flange connectors, to join pipes without welding.

- Procedure:

- Prepare the pipe ends: Cut and clean the ends of the pipes.

- Install the compression fitting: Place the fitting over the ends of the pipes.

- Tighten the fitting: Use a wrench to tighten the nut or bolts on the fitting, compressing the seal inside to create a secure joint.

- Required Tools: Wrench, compression fittings (couplings, tees, elbows, etc.).

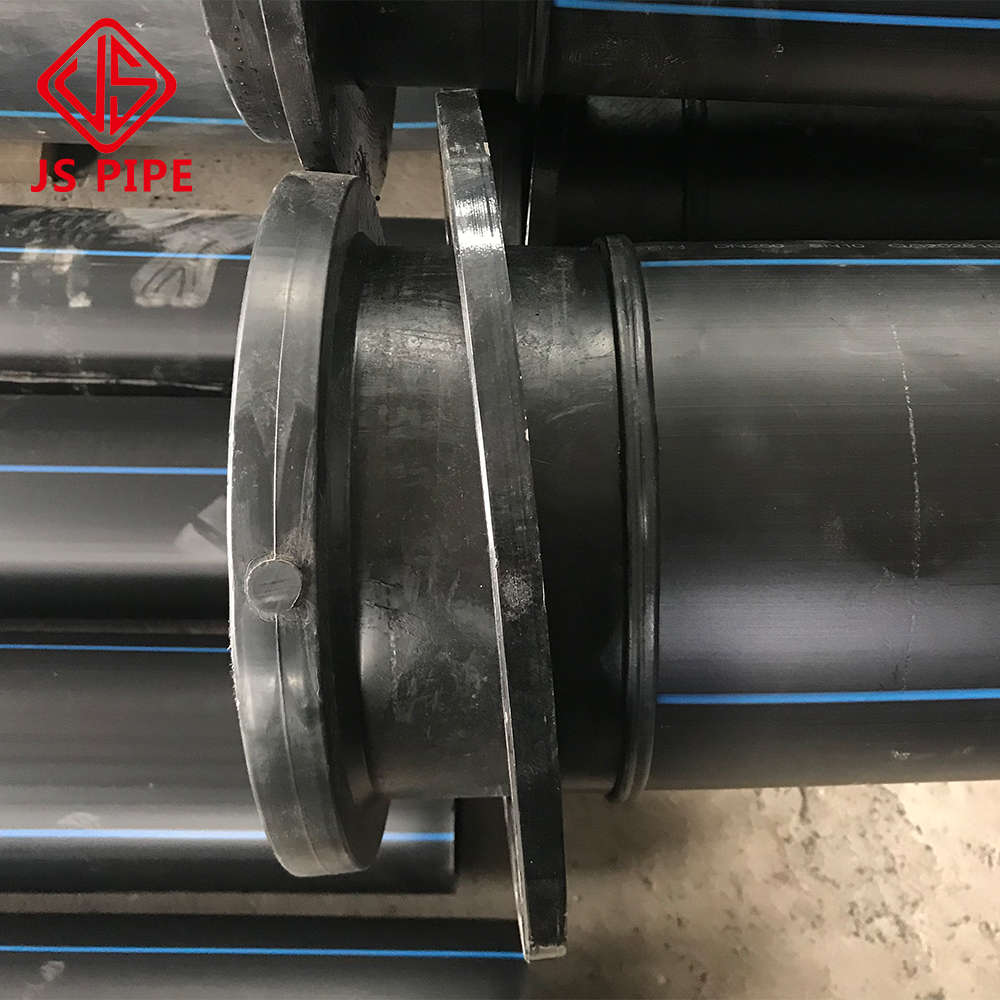

4. Flange Connection

Overview: Flanged connections are suitable for larger diameter pipes. Flanges are fixed to the pipe ends, and bolts are used to fasten the flanges together.

Procedure:

- Attach flanges to the pipe ends: Weld or bolt the flanges onto the ends of the HDPE pipes.

- Align the flanges: Position the two flanged ends so they are properly aligned.

- Secure the flanges: Tighten the bolts in a crisscross pattern to evenly distribute pressure and ensure a leak-proof seal.

Required Tools: Flanges, bolts, gaskets, wrench, and alignment tools.

5. Push-fit (Quick-connect) Fittings

Overview: Push-fit fittings are commonly used for smaller diameter HDPE pipes in simpler, temporary, or low-pressure situations.

Procedure:

- Cut and clean the pipe ends: Make sure the ends are smooth and free of dirt or debris.

- Insert the pipe into the fitting: Push the pipe into the fitting until it locks securely.

Required Tools: Push-fit fittings (such as couplings and elbows).

6. Socket Fusion (for smaller pipes)

Overview: Socket fusion is akin to butt fusion but is generally used for smaller diameter pipes, involving the insertion of one pipe end into a heated fitting.

Procedure:

- Prepare the pipes: Cut and clean the ends of the pipes and fittings.

- Heat the fitting and pipe: Use a socket fusion tool to heat the ends of the pipe and fitting.

- Connect the components: Once heated, quickly insert the pipe into the fitting and allow it to cool and bond.

Required Tools: Socket fusion tool, pipe cutter.

General Advice for HDPE Pipe Connections:

- Ensure proper alignment: Misalignment can result in weak joints or leaks.

- Monitor the temperature: For fusion methods, ensure the heating temperatures are correct for effective fusion.

- Adhere to manufacturer specifications: Different HDPE pipes and fittings may have varying requirements, so always refer to the manufacturer's guidelines.

- Conduct pressure testing: After making any connection, perform a pressure test to confirm that the joint is secure and leak-free.

Each connection method has its advantages and disadvantages, and the most suitable option for your project will depend on the pipe size, pressure needs, and available tools. Butt fusion and electrofusion are typically preferred for permanent, high-strength connections, while compression fittings or push-fit methods are generally easier for temporary or lower-pressure applications.

You are welcome to : phone call, Message, Wechat, Email& Seaching us, etc.