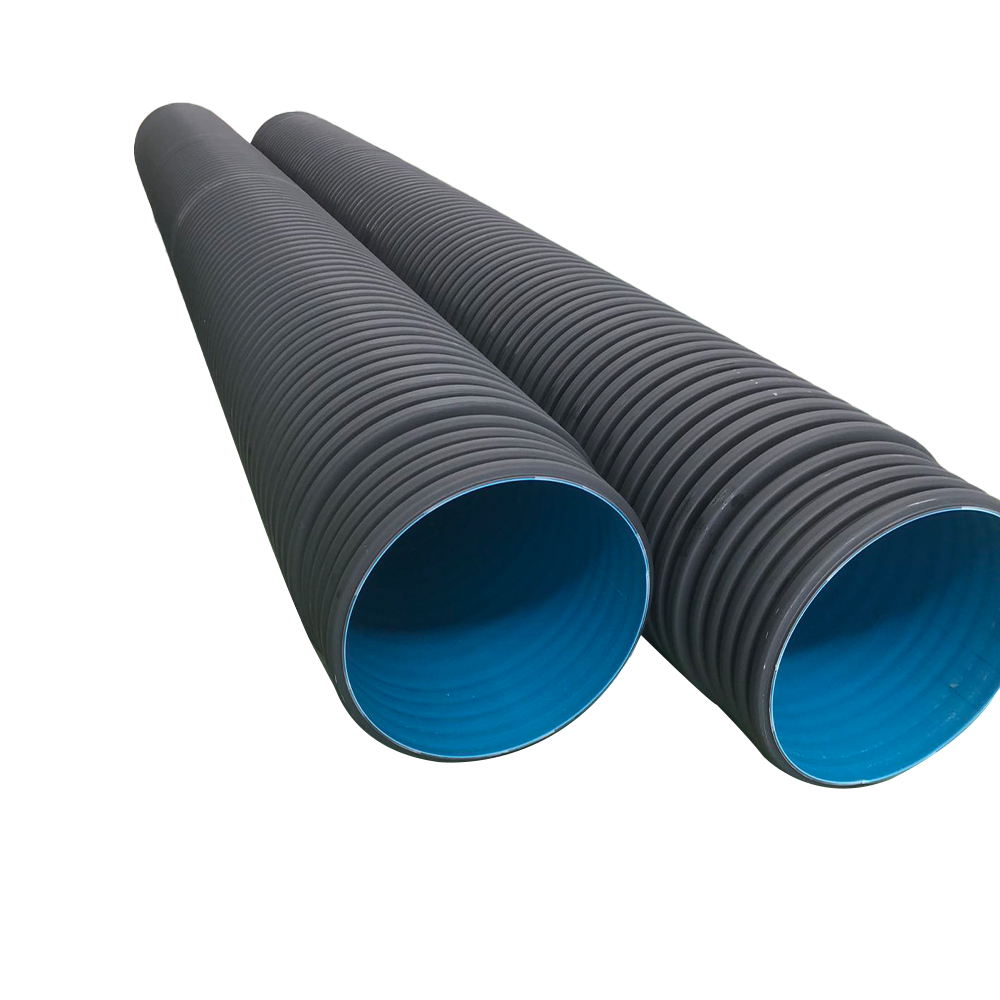

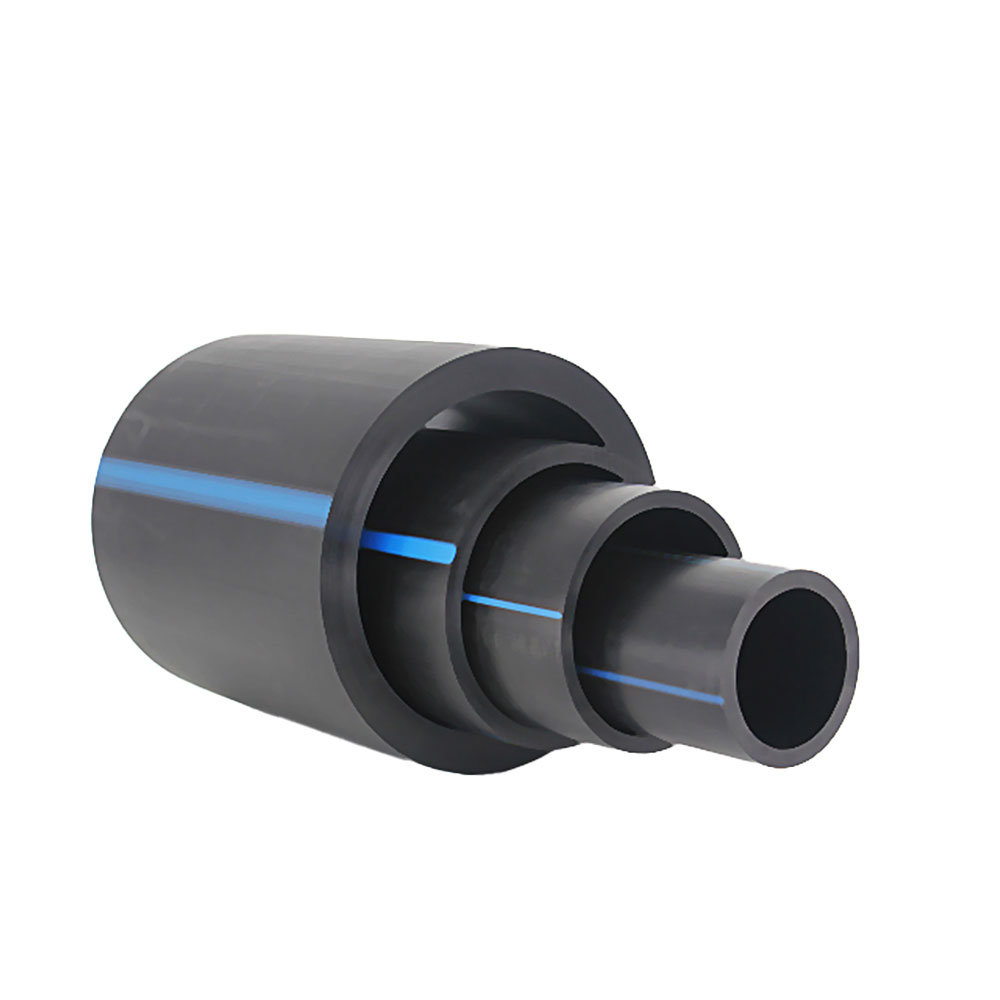

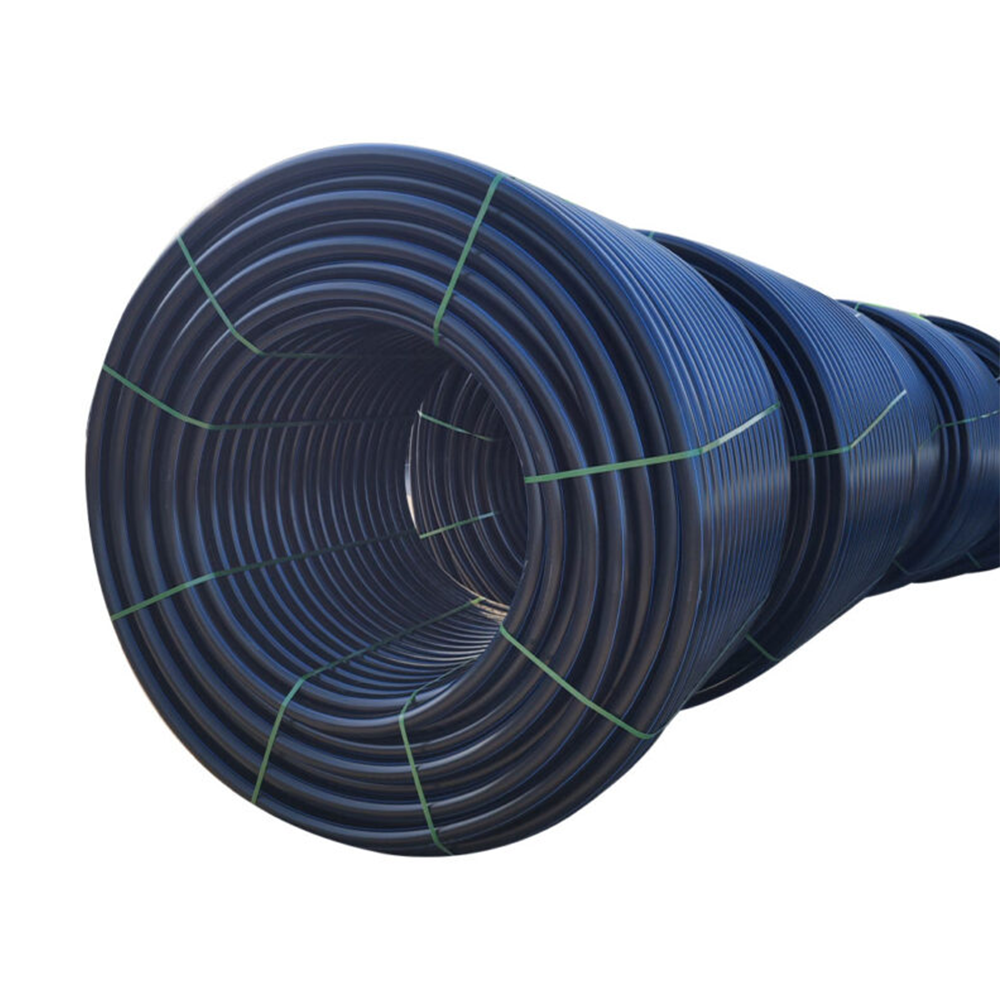

Installation of HDPE (High-Density Polyethylene) underground pipelines has been widely utilized in municipal, hydraulic, and industrial sectors due to its outstanding characteristics such as excellent corrosion resistance, flexibility, and sealing properties. Correct installation methods are crucial to ensuring the performance and longevity of the pipeline system. So, how to install underground conduit? Below are the methods we provide:

Preparation before Installation

- Design Planning

Before installing HDPE underground pipelines, detailed design planning is required based on project requirements and site conditions. This includes determining the pipeline route, selecting pipe diameters, and establishing burial depths. - Material Inspection

Conduct quality inspections on purchased HDPE pipes and related fittings to check for defects in appearance, compliance with standards in dimensions, and material qualifications. - Construction Site Preparation

Clear the construction site to ensure a flat, obstacle-free surface, providing a good working environment for pipeline installation. - Construction Equipment Preparation

Prepare the necessary construction equipment such as excavators, hot fusion welders, cranes, ensuring the equipment is in good working condition.

Installation Process

- Trench Excavation

Excavate trenches according to design requirements, controlling the depth, width, and slope of the trench. Simultaneously, take necessary shoring measures to prevent trench collapse. - Pipeline Installation

Lift the HDPE pipes into the trench, handling them with care to avoid damage.Arrange and connect the pipes according to design specifications, typically using methods like hot fusion or electrofusion welding.During the connection process, strictly control parameters such as temperature, time, and pressure to ensure connection quality. - Backfilling

Use supports or wedges to secure the pipes in the trench, preventing displacement during backfilling.Once the pipeline installation is complete and passes inspection, begin backfilling.Use suitable sand or fine soil for backfilling, layering and compacting it to ensure quality.

Post-Installation Inspection and Maintenance

- Inspection

Conduct hydrostatic pressure tests to check the sealing of the pipeline system.Inspect the appearance and connection points of the pipes to ensure there are no damages or leaks. - Maintenance

Regularly inspect the pipes to promptly identify and address damages and faults.Perform necessary cleaning and maintenance to extend the pipeline's lifespan.

The Burial Depth of HDPE Pipes

- Local Regulations

Regulations may vary in different regions, so it is crucial to comply with all local laws. Contact the local regulatory office to ensure you have the correct information. - Industry Standards

Additionally, you need to ensure compliance with all industry standards such as ASTM, AASHTO, NEMA, and NEC specifications. - Pipe Type

The specific dimensions and thickness of the pipe will affect the required burial depth. Thicker-walled HDPE pipes can offer better protection and may be suitable for shallower burial, whereas thinner-walled HDPE pipes may require deeper burial. Consult the specifications for recommended burial depths. - Ground Conditions

Rocks and compacted soil provide more protection than loose or sandy soil. Generally, rocks and compacted soil can be buried shallower, while in loose and sandy soils, deeper burial is required to prevent damage. - Traffic Conditions

In general, when HDPE pipes are installed in areas with convenient traffic access, the burial depth should be deeper compared to areas with no traffic. Deeper burial depths can withstand additional weight in live load areas.

Conclusion

The installation of underground HDPE Pipes is a complex and crucial engineering task that must be carried out in strict adherence to relevant specifications and standards. Adequate preparation before installation, stringent quality control during the installation process, timely inspection, and maintenance post-installation are essential to ensure the safety, stable operation, and optimal functionality of the pipeline system.

You are welcome to : phone call, Message, Wechat, Email& Seaching us, etc.