When it comes to HDPE fusion welding machines, there is a critical investment that is often underestimated – one that has the potential to reduce future expenses.

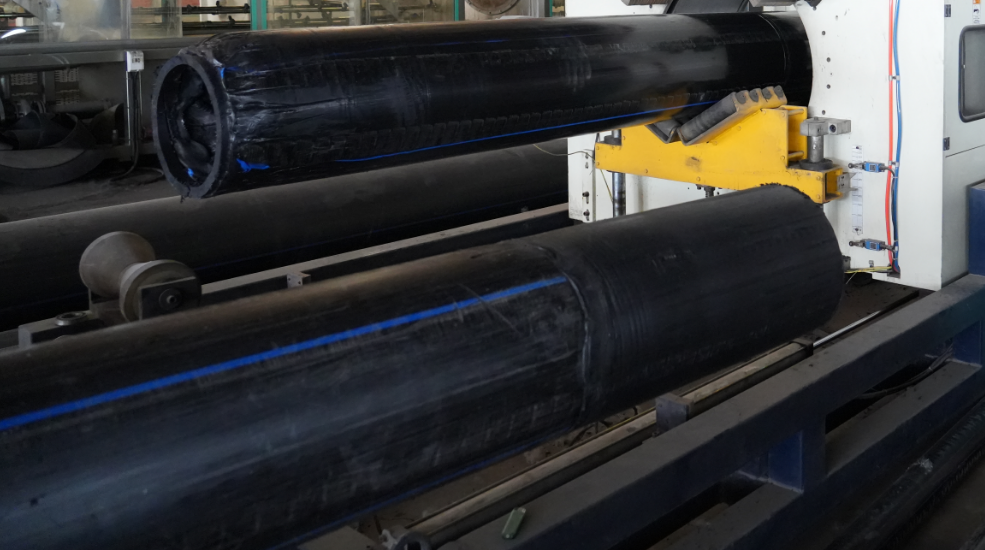

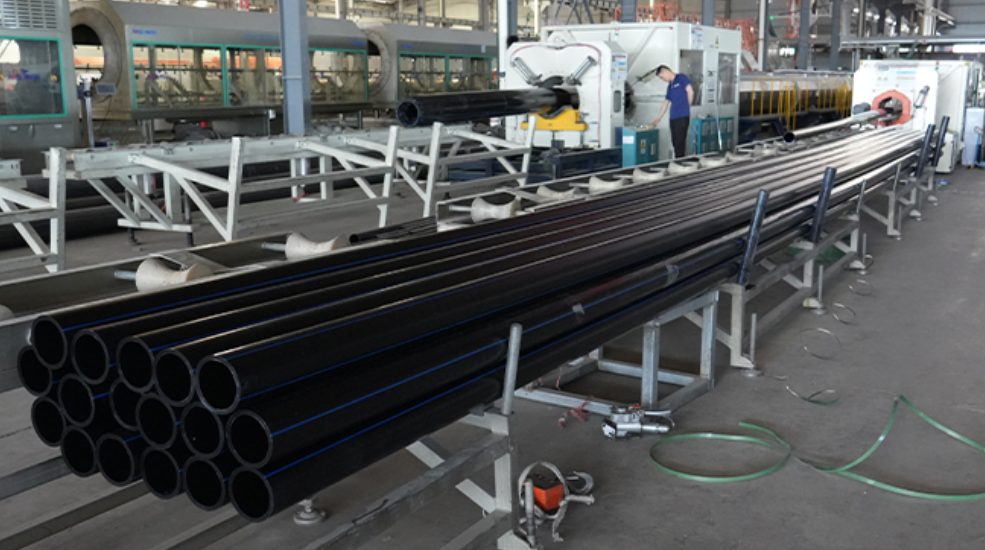

High-density polyethylene (HDPE) is a tough and durable plastic that maintains its structural integrity even under heavy loads. However, it is important to ensure that the pipes you use have appropriate ratings to withstand the size and duration of the loads they need to bear. At JS PIPE, we manufacture durable pipes suitable for heavy commercial and industrial applications.

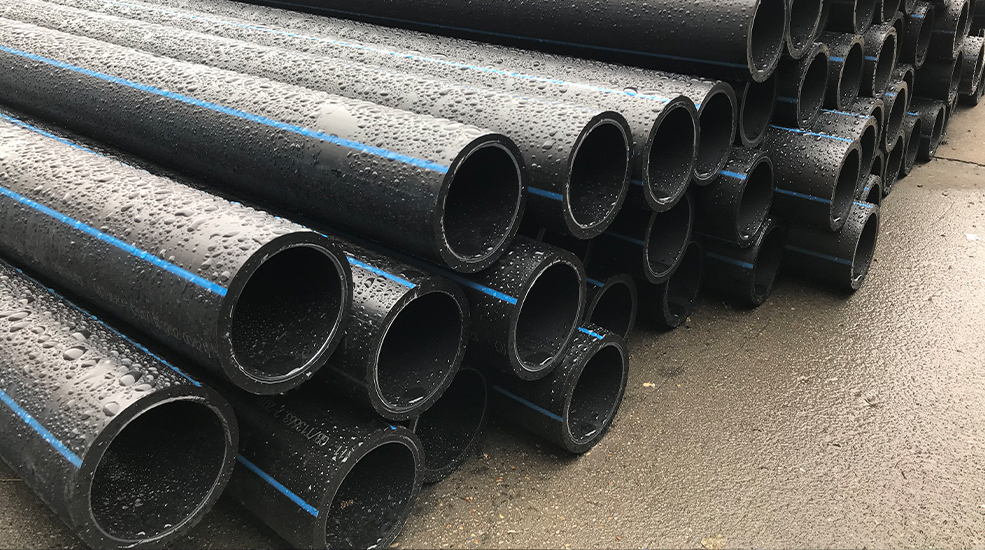

In today’s era of emphasis on sustainability and environmental protection, it is crucial to choose pipeline materials that are energy-efficient and eco-friendly. HDPE pipes, which do not contain heavy metal additives and are resistant to bacterial growth and structural issues, provide a significant solution to the problem of drinking water pollution. Furthermore, HDPE pipes exhibit strong corrosion resistance, are non-polluting, have smooth inner walls, extremely low friction coefficients, excellent wear resistance, and ensure smooth drainage.

HDPE (High-Density Polyethylene) water pipes have gained popularity due to their unique structural design and advantageous features. This article will focus on the structural characteristics of HDPE water pipes and the advantages they bring, explaining why you should choose HDPE water pipes.

High-density polyethylene (HDPE) is a thermoplastic plastic known for its excellent tensile strength, corrosion resistance, and impact resistance. These characteristics make it an ideal material choice for various applications, including both pressure and non-pressure pipelines, conduits, and drainage systems. HDPE pipes are used in drinking water systems, mining operations, oil and gas collection, wastewater treatment, protection of fiber optic cables, natural gas distribution, and more.

UPVC pipes (Unplasticized Polyvinyl Chloride pipes) are a type of piping made from polyvinyl chloride (PVC) material. They possess advantages such as acid and alkali…

With increasing engineering requirements, steel pipes gradually fail to meet market demands, leading to the emergence of HDPE dredging pipes.

In modern architecture and drainage systems, PVC drainage pipes have become widely used due to their unique advantages.

An HDPE pipe welding machine is an essential tool for safely connecting HDPE pipes and fittings. Its technical specifications make it suitable for various welding and manufacturing applications.

The electro fusion welding machine has gained more attention as a crucial tool for connecting HDPE pipes, thanks to its efficiency and reliability.

HDPE (High-Density Polyethylene) pipes and PVC (Polyvinyl Chloride) pipes are two common types of plastic pipes widely used in various fields such as construction, municipal engineering, and agriculture. However, they have some differences in terms of material, usage, characteristics, and applications.

Drip tapes and porous soaker hoses are two common components used in irrigation systems, and they have some differences in design and functionality.