Pipeline installation is a crucial part of many infrastructure and construction projects, from transporting water and gas to installing drainage systems. However, the process of pipeline installation comes with its own set of challenges. Poor planning, difficult terrain, weather conditions, and technical issues can all pose obstacles to the successful completion of a project. In this blog, we will explore common issues faced during installing pipelines and offer practical solutions to ensure smooth and efficient pipeline installation.

Common Challenges in Pipeline Installation

Complex Terrain and Environmental Obstacles

One of the most common challenges in pipeline installation is dealing with complex or uneven terrain. Installing pipelines across hilly or rocky areas, wetlands, or areas with poor soil conditions can lead to additional costs and time delays. Additionally, environmental concerns, such as protecting natural habitats and minimizing disruptions to local wildlife, are increasingly important in many pipeline projects.

Weather Conditions

Extreme weather conditions, such as heavy rainfall, freezing temperatures, or intense heat, can create significant delays during the installation pipeline process. Rain can lead to flooding in excavation sites, making it impossible to continue working. Meanwhile, cold weather can cause freezing of pipes or delays in welding, and excessive heat can make it unsafe for workers.

Material Supply and Logistics

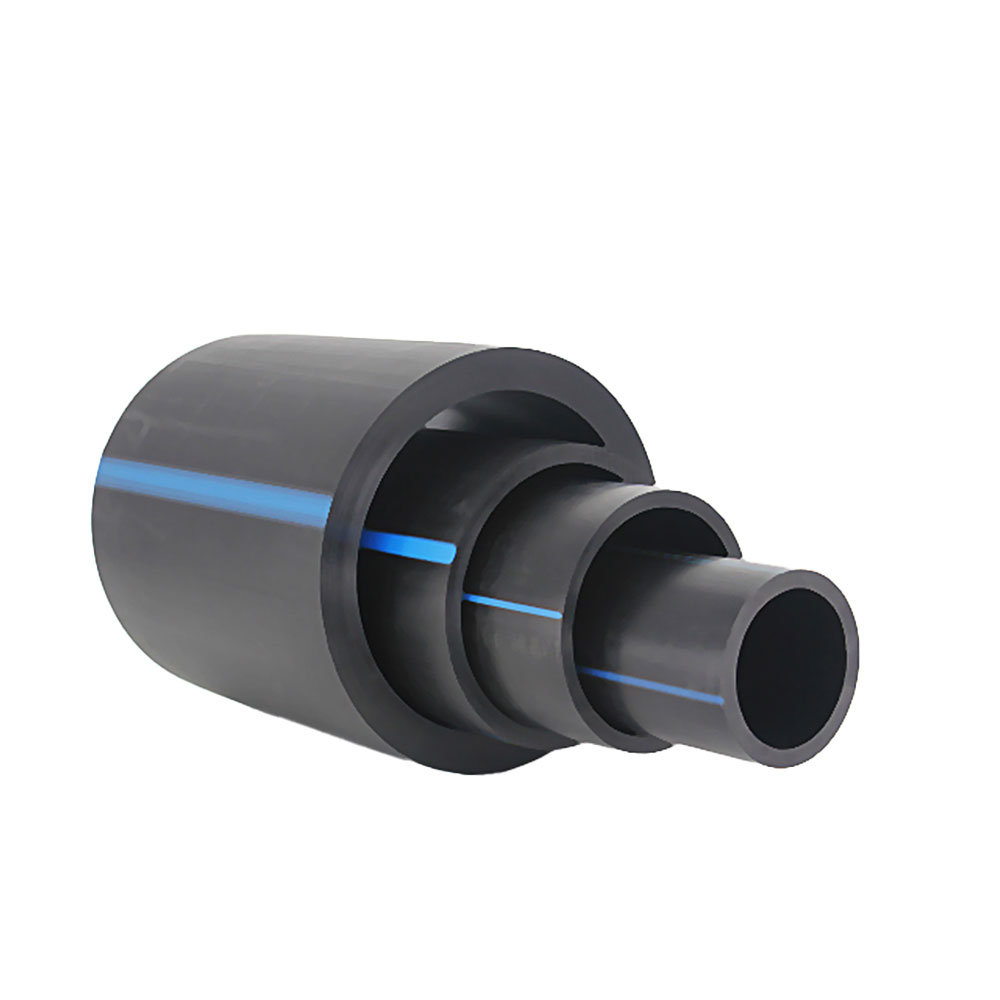

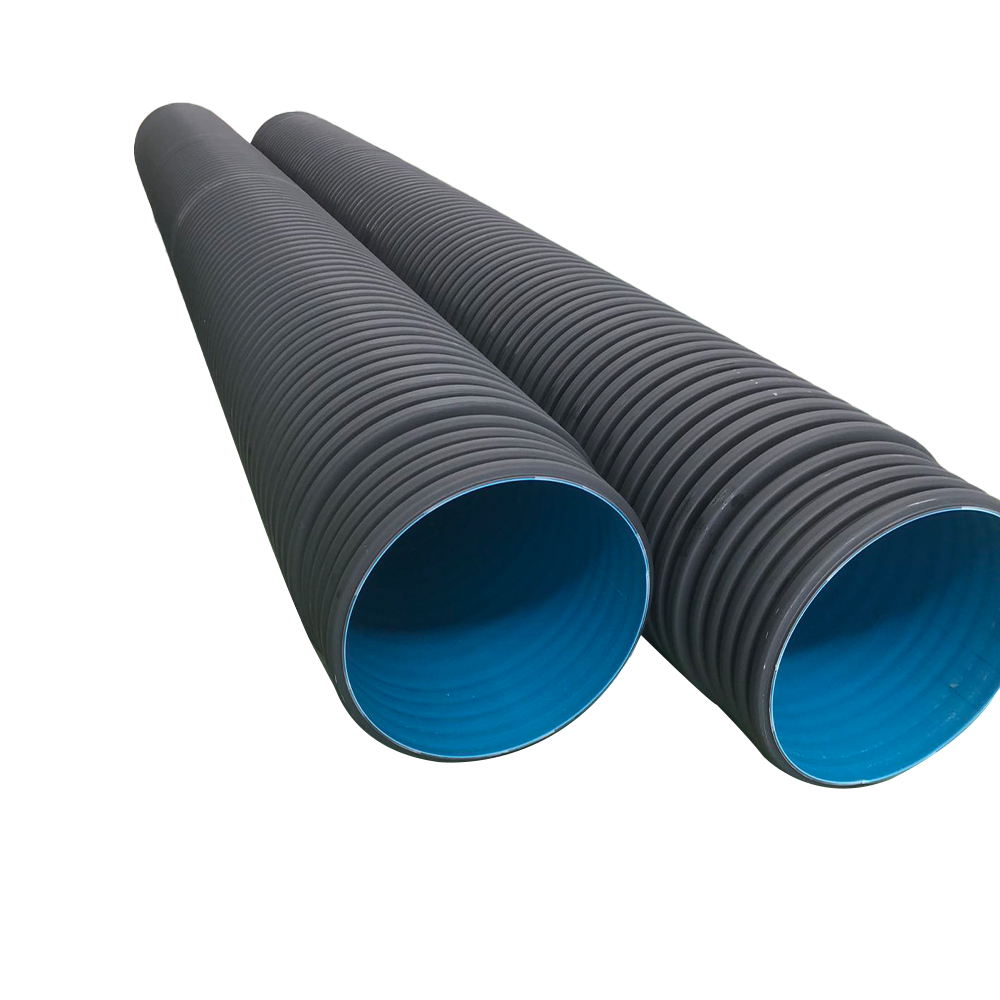

A major factor in any pipeline project is ensuring that the materials arrive on time and in good condition. Delays in the delivery of pipes, fittings, or other necessary equipment can halt progress on the project. Poor-quality materials can also lead to future issues such as leaks or pipe bursts. Managing the supply chain efficiently and ensuring quality control is essential.

Design and Engineering Challenges

Errors in pipeline design or engineering can lead to significant problems once installation begins. For example, if the pipeline’s capacity is underestimated or if the wrong type of pipe is used for the terrain, costly modifications may be required during construction. Design flaws can also lead to increased risk of leaks, breaks, or blockages in the future.

Safety Risks

The safety of workers is always a concern during pipeline installation. Working in confined spaces, near heavy machinery, or in hazardous environments presents risks that must be managed effectively. Ensuring that safety protocols are followed and that workers are properly trained can prevent accidents and ensure a smoother installation process.

Solutions to Overcome Pipeline Installation Challenges

Pre-Installation Planning and Site Assessment

One of the best ways to mitigate the challenges of pipeline installation is through thorough planning and site assessment. Conducting a detailed survey of the terrain and environment before installation can help identify potential issues such as unstable soil, water bodies, or other obstacles. Once these issues are identified, adjustments can be made to the installation plan to ensure that the project stays on track.

For example, if a pipeline install is set to take place in an area prone to flooding, raising the pipes above ground on supports or using specialized drainage systems can help mitigate the risk of water damage. Similarly, in areas with difficult terrain, directional drilling or horizontal boring may be used to avoid unnecessary excavation.

Weather Forecasting and Contingency Planning

Weather is an unavoidable factor in any outdoor project, but it doesn’t have to completely derail progress. By closely monitoring weather forecasts and implementing contingency plans, project managers can minimize the impact of extreme weather on pipeline installation.

For instance, if rain is expected during the excavation phase, crews can prepare the site by installing temporary drainage or protective covers to prevent water accumulation. In cold-weather environments, installing heating equipment to prevent pipe freezing or scheduling work during milder temperatures can help avoid delays.

Efficient Material Procurement and Logistics Management

Ensuring the timely and safe delivery of materials is critical for any installation pipeline project. To avoid delays due to late deliveries, project managers should work closely with suppliers to create a reliable schedule. Additionally, using local suppliers can minimize transportation time and reduce the likelihood of damage during transit.

It's also important to inspect materials upon arrival to ensure they meet quality standards. Using low-quality or damaged pipes can lead to future repairs, increasing the overall cost of the project. Having backup suppliers in place can also ensure that materials are available in case of unexpected supply chain disruptions.

Advanced Design and Engineering Solutions

When it comes to installing pipelines, getting the design right is key to a successful project. Using advanced design tools such as 3D modeling and simulation software can help engineers visualize the pipeline and identify potential issues before construction begins. This ensures that the pipeline is suited to the terrain and that its capacity will meet future demand.

Additionally, working closely with engineers throughout the project can help solve any design challenges that arise. For example, if a design flaw is discovered after installation has started, engineers can work on-site to come up with alternative solutions, such as rerouting sections of the pipeline or using different materials.

Safety Protocols and Training

Safety should always be a top priority in any pipeline install project. Providing workers with the right safety equipment and ensuring they are properly trained on how to use it can prevent accidents. Additionally, conducting regular safety briefings and inspections ensures that everyone on-site is following the correct protocols.

In high-risk environments, such as when working with hazardous materials or in confined spaces, it may also be beneficial to employ specialized workers with experience in handling these situations. This not only ensures safety but also improves efficiency by reducing the likelihood of accidents that could cause delays.

Innovative Installation Techniques

Utilizing modern installation techniques can help overcome many of the common challenges associated with pipeline projects. For example, trenchless technology is a method that allows pipelines to be installed underground without the need for extensive digging. This technique is particularly useful in urban areas or locations where digging would disrupt existing infrastructure or the environment.

Other techniques, such as pipe-jacking and microtunneling, can also be used to install pipelines in areas with challenging terrain. These methods are less invasive and require less excavation, making them ideal for minimizing disruption to the environment and reducing overall installation time.

Monitoring and Maintenance Post-Installation

The work doesn’t stop once the pipeline is installed. Regular monitoring and maintenance are essential to ensure that the pipeline remains in good condition and functions as intended. By installing sensors and monitoring systems, any issues such as leaks, blockages, or corrosion can be detected early and addressed before they become major problems.

Routine inspections and maintenance can also extend the lifespan of the pipeline, reducing the need for costly repairs or replacements in the future. Having a comprehensive maintenance plan in place ensures the long-term success of the project.

Conclusion

Pipeline installation can be a complex and challenging process, but with proper planning, the right tools, and innovative solutions, many of the common obstacles can be overcome. From site assessments and weather forecasting to advanced design techniques and safety protocols, each aspect of the installation must be carefully considered to ensure a successful project.

By addressing these challenges head-on, project managers can ensure that pipelines are installed efficiently, safely, and with minimal environmental impact. Whether you are working on a small residential project or a large industrial pipeline, understanding and anticipating the challenges of installing pipelines is the key to success.

You are welcome to : phone call, Message, Wechat, Email& Seaching us, etc.