High-density polyethylene (HDPE) is a tough and durable plastic that maintains its structural integrity even under heavy loads. However, it is important to ensure that the pipes you use have appropriate ratings to withstand the size and duration of the loads they need to bear. At JS PIPE, we manufacture durable pipes suitable for heavy commercial and industrial applications.

Let's delve into more information about standard dimension ratio (SDR) and selecting the right pipes for your project.

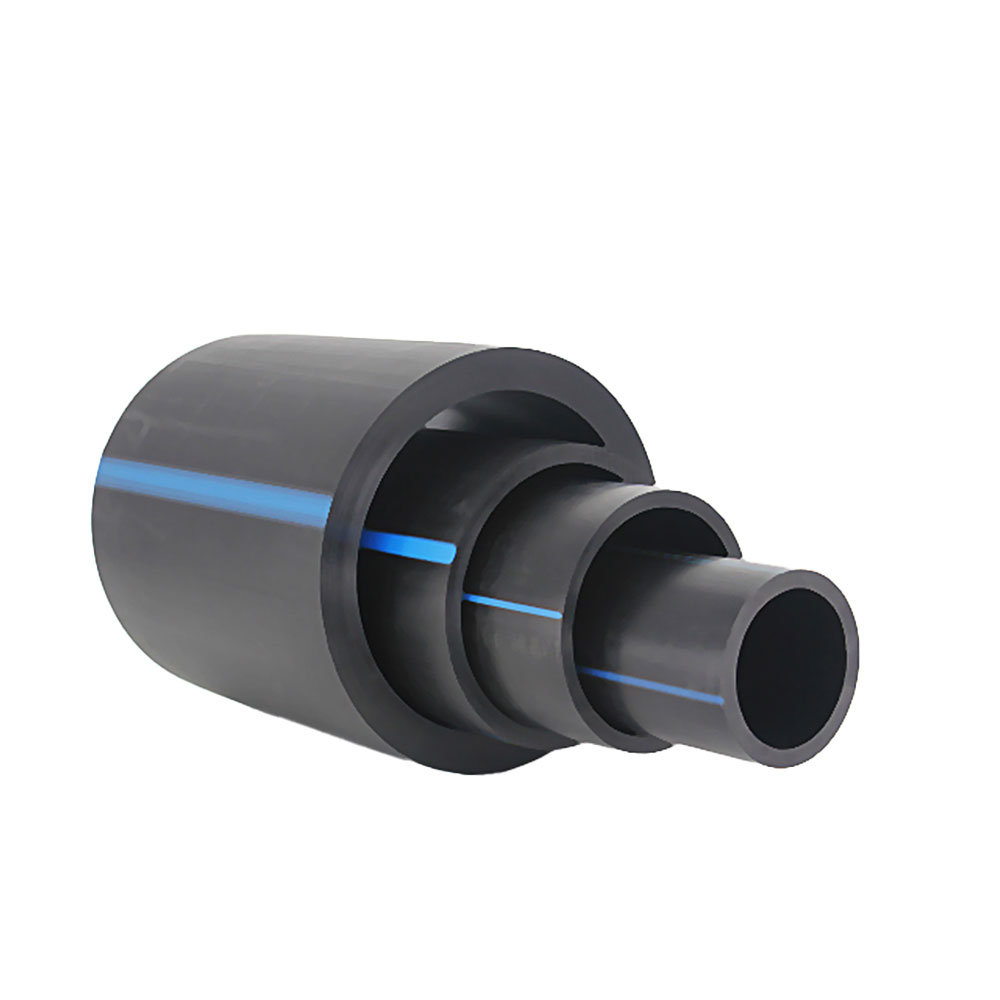

Standard Dimension Ratio (SDR), also known as Standard Dimension Ratio, is a measurement method frequently used by pipe manufacturers to evaluate the working pressure capacity of pipes. It is calculated by determining the relationship between the outer diameter of the pipe and its minimum wall thickness. The higher the calculated SDR value, the lower the pressure the pipe can withstand, as the minimum wall thickness decreases proportionately to the outer diameter. Conversely, the lower the calculated SDR value, the higher the pressure the pipe can withstand, as the wall thickness increases proportionally with the pipe diameter. For example, a pipe with an SDR of 17 has a thinner wall compared to SDR 11 and therefore has a lower pressure rating. Understanding and grasping this value is crucial for many applications, including but not limited to:

- Calculating internal pressure within the pipe system

- Inserting objects into the pipe system, such as ID reinforcements for compression fittings

- Determining the tensile strength of pipes under high stress

- Evaluating the compressive strength of buried pipes

What is the difference between SDR and DR?

The terms Standard Dimension Ratio (SDR) and Dimension Ratio (DR) refer to the same ratio, which is the ratio of the average outer diameter of the pipe to the minimum wall thickness. They were developed to assist industry professionals in standardizing how pipe specifications are represented internationally, thus helping to minimize confusion between procurement agents and end-users. The main difference between them is that DR can be used for any number, whereas SDR is used for specific series of numbers (such as 17, 11, 9, 7, etc.). This series is based on a geometric series pattern developed by the French engineer Charles Renard. If the ratio of the pipe is not one of Renard's numbers, it cannot be referred to as SDR[X]; it can only be referred to as DR[X].

As mentioned above, a higher SDR/DR value means a lower minimum wall thickness for the pipe while keeping the outer diameter constant, and a lower SDR/DR value means a thicker minimum wall thickness for the pipe while keeping the outer diameter constant. This means that two pipes with the same OD but different DR values will have different wall thicknesses. For example, a 14-inch OD pipe with a wall thickness of 1.273 inches has a DR of 11, while a 14-inch pipe with a wall thickness of 0.824 inches has a DR of 17.

How to determine the SDR of a pipe?

The SDR ratio is sometimes expressed as OD/t, with a relatively simple formula:

Here, "OD" refers to the average outer diameter of the pipe, and "mn" refers to the minimum wall thickness of the pipe. If you don't have the numbers needed for the calculation, you can physically measure the opening end of the pipe using a caliper. Alternatively, you can check the product markings to see if the pipe is labeled with DR/SDR.

If you want to learn more about the standard dimension ratio and its relationship with pipes, consult the experts at JS PIPE. We have extensive experience in manufacturing HDPE pipes for various applications, and we have the knowledge and skills to address and resolve any questions or concerns you may have regarding pipes.

You are welcome to : phone call, Message, Wechat, Email& Seaching us, etc.