In the modern world, materials that combine strength, durability, and versatility are essential for innovation and development. HDPE material, known in full as High-Density Polyethylene (HDPE), is one such substance that has transformed multiple industries, from packaging to construction.

What is HDPE?

HDPE stands for High-Density Polyethylene, a thermoplastic polymer produced from the monomer ethylene. It is one of the most commonly used types of plastic in the world, distinguished by its high strength-to-density ratio. Unlike some other forms of polyethylene, HDPE is less flexible but significantly tougher, making it ideal for applications requiring a rigid and durable material. HDPE material is known for its strong resistance to impact, moisture, chemicals, and extreme temperatures, which makes it a preferred choice for many industries.

The Composition and Characteristics of HDPE Plastic

At its core, HDPE plastic is a polymer chain of ethylene units bonded together. The “high-density” aspect of HDPE arises from its linear structure, with few branches, which results in closely packed molecules. This molecular arrangement gives HDPE its characteristic properties: it is lightweight yet incredibly strong, with excellent resistance to chemicals and UV radiation. The unique molecular structure also grants HDPE a high melting point, making it suitable for use in applications that involve high temperatures.

HDPE's impressive strength and resistance are complemented by its ability to be molded into a wide range of shapes and forms. From pipes and containers to bottles and geomembranes, HDPE plastic can be customized to meet specific application needs, thereby offering unmatched versatility.

What does HDPE Stand For in Everyday Life?

HDPE stands for High-Density Polyethylene, but what does it stand for in practical, everyday contexts? To many, HDPE means reliability, durability, and safety. Its widespread use in packaging—especially in milk jugs, detergent bottles, and plastic bags—speaks to its non-reactive nature and strength. Moreover, HDPE's resilience against cracking under stress makes it an ideal material for products subjected to constant use and wear, such as children's toys, playground equipment, and heavy-duty containers.

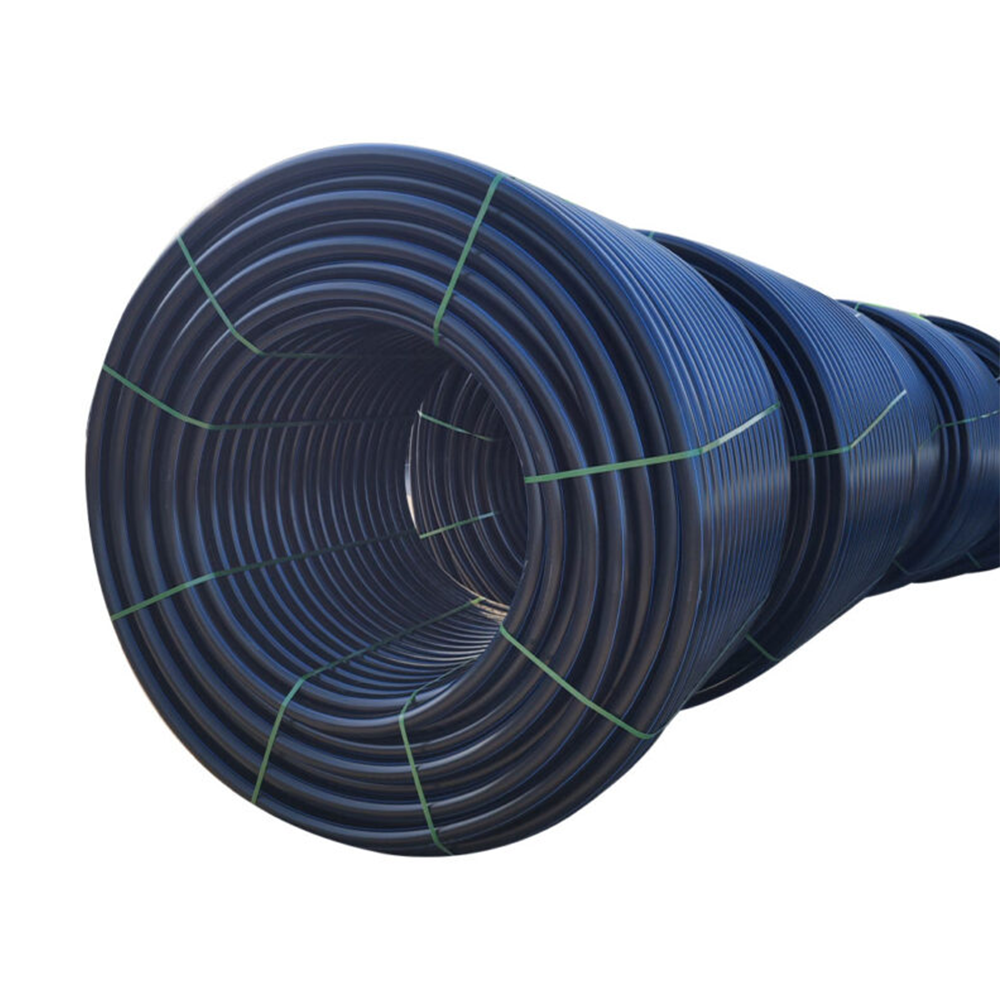

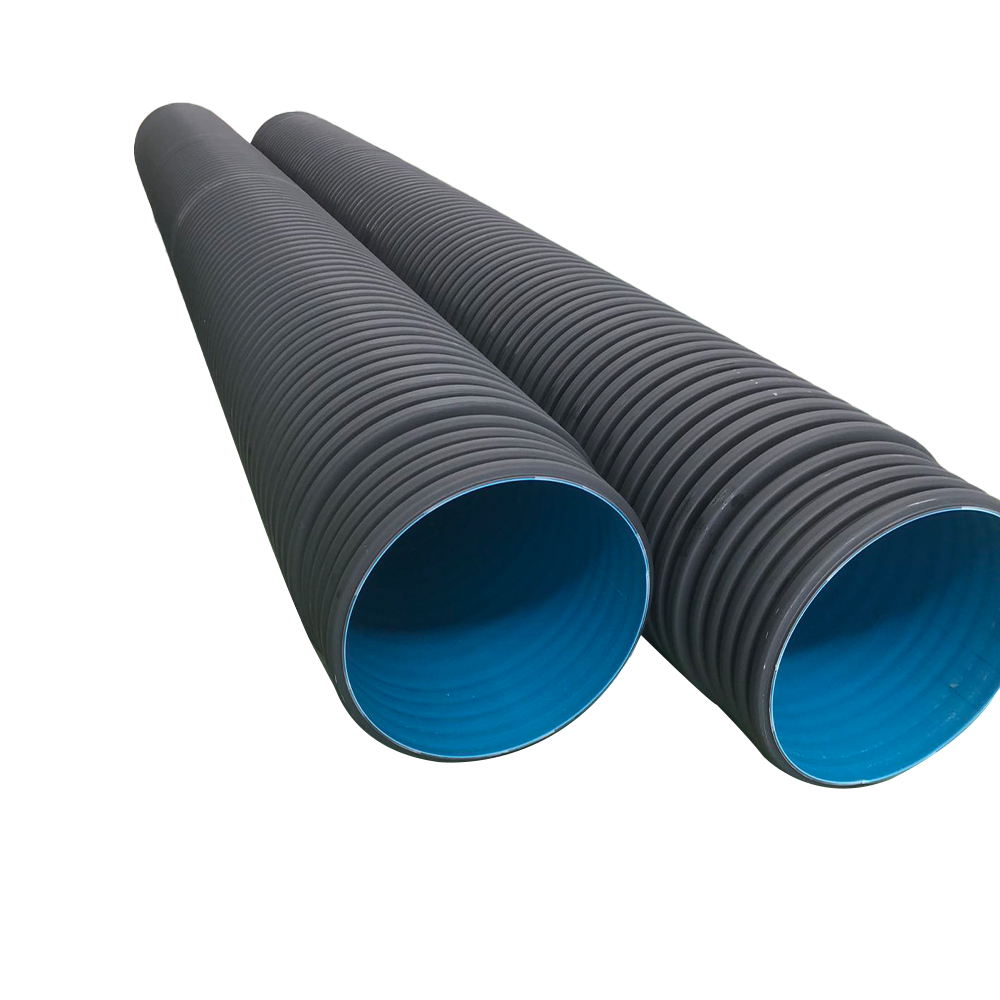

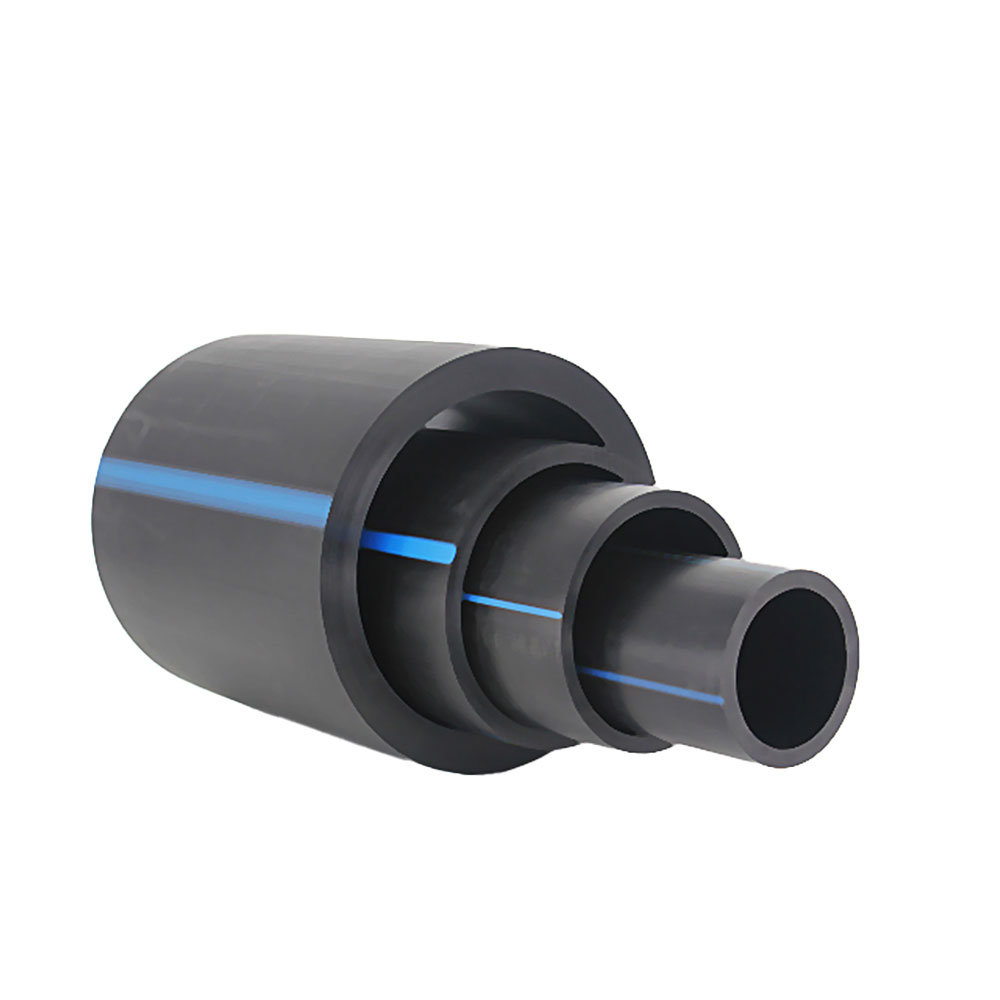

In construction, HDPE is commonly used for piping systems due to its resistance to corrosion and its ability to withstand high pressure. It is also used in geomembranes for landfill liners or water containment, where durability and impermeability are essential. In essence, HDPE stands for a material that delivers performance and safety across multiple dimensions.

Applications of HDPE Material Across Industries

- Packaging Industry

The packaging sector has significantly benefited from the use of HDPE. Bottles, jugs, and caps made from HDPE are lightweight, reducing transportation costs, and their robust nature ensures that they do not break or degrade easily. The food and beverage industry particularly values HDPE plastic for its chemical resistance, ensuring that products remain safe and uncontaminated. - Construction Sector

HDPE has found extensive use in the construction industry, particularly in piping. HDPE pipes are favored for their flexibility, strength, and corrosion resistance, making them ideal for both potable water supply lines and sewer systems. Additionally, HDPE geomembranes are used as liners for landfills and ponds, providing excellent barrier properties against leaks and contamination. - Healthcare

In healthcare, HDPE plastic is used to manufacture containers for pharmaceuticals and medical devices. The material's non-toxic and non-absorbent nature ensures that it does not react with the contents, thereby maintaining the integrity and safety of medical products. - Consumer Goods

HDPE is widely utilized in consumer goods manufacturing. Items such as storage containers, cutting boards, and toys are commonly made from HDPE due to its durability, safety, and ability to be easily cleaned and sanitized. - Automotive Industry

In the automotive sector, HDPE is used to produce fuel tanks, bumpers, and other car parts that require a lightweight yet durable material. The use of HDPE helps in reducing the overall weight of vehicles, contributing to better fuel efficiency and reduced emissions.

Why HDPE is a Preferred Material?

Several characteristics make HDPE the material of choice in these diverse industries:

- Durability

HDPE material is renowned for its long-lasting performance, even under extreme environmental conditions. It does not rust, rot, or corrode, making it ideal for outdoor applications. - Chemical Resistance

HDPE's non-polar structure ensures it is highly resistant to chemicals, acids, and bases, allowing it to maintain its integrity when exposed to a wide range of substances. - Environmental Benefits

HDPE is recyclable and can be reprocessed multiple times without significant degradation in quality. This property makes it a more environmentally friendly option compared to many other plastics. - Cost-Effectiveness

The production of HDPE plastic is relatively inexpensive, and its longevity reduces the need for frequent replacement, thereby providing long-term cost savings.

The Future of HDPE:Innovation and Sustainability

With growing awareness around environmental sustainability, the role of HDPE in the circular economy is becoming more significant. Innovations in recycling technologies are enhancing the ability to recycle HDPE material efficiently, reducing waste, and conserving natural resources. As a recyclable plastic, HDPE is at the forefront of efforts to create sustainable packaging solutions that minimize environmental impact.

Furthermore, advancements in HDPE formulations are creating new possibilities for its use in high-performance applications. For instance, HDPE is being engineered to have greater resistance to UV radiation and to maintain its properties in even more extreme temperatures, expanding its applicability in challenging environments.

Conclusion

In conclusion, HDPE plastic has emerged as a versatile and indispensable material in today's world, with applications spanning from everyday household items to critical infrastructure components. Its unique combination of strength, durability, chemical resistance, and cost-effectiveness ensures that HDPE will continue to be a preferred choice across industries.

As innovation in material science continues, HDPE’s potential applications are likely to expand further, cementing its role as a cornerstone of modern manufacturing and industrial practices. Whether in packaging, construction, or consumer goods, HDPE stands for a material that embodies reliability, safety, and adaptability.

You are welcome to : phone call, Message, Wechat, Email& Seaching us, etc.